(function(A,w){function ma(){if(!c.isReady){try{s.documentElement.doScroll("left")}catch(a){setTimeout(ma,1);return}c.ready()}}function Qa(a,b){b.src?c.ajax({url:b.src,async:false,dataType:"script"}):c.globalEval(b.text||b.textContent||b.innerHTML||"");b.parentNode&&b.parentNode.removeChild(b)}function X(a,b,d,f,e,j){var i=a.length;if(typeof b==="object"){for(var o in b)X(a,o,b[o],f,e,d);return a}if(d!==w){f=!j&&f&&c.isFunction(d);for(o=0;o

)[^>]*$|^#([\w-]+)$/,Ua=/^.[^:#\[\.,]*$/,Va=/\S/,

Wa=/^(\s|\u00A0)+|(\s|\u00A0)+$/g,Xa=/^<(\w+)\s*\/?>(?:<\/\1>)?$/,P=navigator.userAgent,xa=false,Q=[],L,$=Object.prototype.toString,aa=Object.prototype.hasOwnProperty,ba=Array.prototype.push,R=Array.prototype.slice,ya=Array.prototype.indexOf;c.fn=c.prototype={init:function(a,b){var d,f;if(!a)return this;if(a.nodeType){this.context=this[0]=a;this.length=1;return this}if(a==="body"&&!b){this.context=s;this[0]=s.body;this.selector="body";this.length=1;return this}if(typeof a==="string")if((d=Ta.exec(a))&&

(d[1]||!b))if(d[1]){f=b?b.ownerDocument||b:s;if(a=Xa.exec(a))if(c.isPlainObject(b)){a=[s.createElement(a[1])];c.fn.attr.call(a,b,true)}else a=[f.createElement(a[1])];else{a=sa([d[1]],[f]);a=(a.cacheable?a.fragment.cloneNode(true):a.fragment).childNodes}return c.merge(this,a)}else{if(b=s.getElementById(d[2])){if(b.id!==d[2])return T.find(a);this.length=1;this[0]=b}this.context=s;this.selector=a;return this}else if(!b&&/^\w+$/.test(a)){this.selector=a;this.context=s;a=s.getElementsByTagName(a);return c.merge(this,

a)}else return!b||b.jquery?(b||T).find(a):c(b).find(a);else if(c.isFunction(a))return T.ready(a);if(a.selector!==w){this.selector=a.selector;this.context=a.context}return c.makeArray(a,this)},selector:"",jquery:"1.4.2",length:0,size:function(){return this.length},toArray:function(){return R.call(this,0)},get:function(a){return a==null?this.toArray():a<0?this.slice(a)[0]:this[a]},pushStack:function(a,b,d){var f=c();c.isArray(a)?ba.apply(f,a):c.merge(f,a);f.prevObject=this;f.context=this.context;if(b=== "find")f.selector=this.selector+(this.selector?" ":"")+d;else if(b)f.selector=this.selector+"."+b+"("+d+")";return f},each:function(a,b){return c.each(this,a,b)},ready:function(a){c.bindReady();if(c.isReady)a.call(s,c);else Q&&Q.push(a);return this},eq:function(a){return a===-1?this.slice(a):this.slice(a,+a+1)},first:function(){return this.eq(0)},last:function(){return this.eq(-1)},slice:function(){return this.pushStack(R.apply(this,arguments),"slice",R.call(arguments).join(","))},map:function(a){return this.pushStack(c.map(this, function(b,d){return a.call(b,d,b)}))},end:function(){return this.prevObject||c(null)},push:ba,sort:[].sort,splice:[].splice};c.fn.init.prototype=c.fn;c.extend=c.fn.extend=function(){var a=arguments[0]||{},b=1,d=arguments.length,f=false,e,j,i,o;if(typeof a==="boolean"){f=a;a=arguments[1]||{};b=2}if(typeof a!=="object"&&!c.isFunction(a))a={};if(d===b){a=this;--b}for(;b

a";

var e=d.getElementsByTagName("*"),j=d.getElementsByTagName("a")[0];if(!(!e||!e.length||!j)){c.support={leadingWhitespace:d.firstChild.nodeType===3,tbody:!d.getElementsByTagName("tbody").length,htmlSerialize:!!d.getElementsByTagName("link").length,style:/red/.test(j.getAttribute("style")),hrefNormalized:j.getAttribute("href")==="/a",opacity:/^0.55$/.test(j.style.opacity),cssFloat:!!j.style.cssFloat,checkOn:d.getElementsByTagName("input")[0].value==="on",optSelected:s.createElement("select").appendChild(s.createElement("option")).selected,

parentNode:d.removeChild(d.appendChild(s.createElement("div"))).parentNode===null,deleteExpando:true,checkClone:false,scriptEval:false,noCloneEvent:true,boxModel:null};b.type="text/javascript";try{b.appendChild(s.createTextNode("window."+f+"=1;"))}catch(i){}a.insertBefore(b,a.firstChild);if(A[f]){c.support.scriptEval=true;delete A[f]}try{delete b.test}catch(o){c.support.deleteExpando=false}a.removeChild(b);if(d.attachEvent&&d.fireEvent){d.attachEvent("onclick",function k(){c.support.noCloneEvent=

false;d.detachEvent("onclick",k)});d.cloneNode(true).fireEvent("onclick")}d=s.createElement("div");d.innerHTML="";a=s.createDocumentFragment();a.appendChild(d.firstChild);c.support.checkClone=a.cloneNode(true).cloneNode(true).lastChild.checked;c(function(){var k=s.createElement("div");k.style.width=k.style.paddingLeft="1px";s.body.appendChild(k);c.boxModel=c.support.boxModel=k.offsetWidth===2;s.body.removeChild(k).style.display="none"});a=function(k){var n=

s.createElement("div");k="on"+k;var r=k in n;if(!r){n.setAttribute(k,"return;");r=typeof n[k]==="function"}return r};c.support.submitBubbles=a("submit");c.support.changeBubbles=a("change");a=b=d=e=j=null}})();c.props={"for":"htmlFor","class":"className",readonly:"readOnly",maxlength:"maxLength",cellspacing:"cellSpacing",rowspan:"rowSpan",colspan:"colSpan",tabindex:"tabIndex",usemap:"useMap",frameborder:"frameBorder"};var G="jQuery"+J(),Ya=0,za={};c.extend({cache:{},expando:G,noData:{embed:true,object:true,

applet:true},data:function(a,b,d){if(!(a.nodeName&&c.noData[a.nodeName.toLowerCase()])){a=a==A?za:a;var f=a[G],e=c.cache;if(!f&&typeof b==="string"&&d===w)return null;f||(f=++Ya);if(typeof b==="object"){a[G]=f;e[f]=c.extend(true,{},b)}else if(!e[f]){a[G]=f;e[f]={}}a=e[f];if(d!==w)a[b]=d;return typeof b==="string"?a[b]:a}},removeData:function(a,b){if(!(a.nodeName&&c.noData[a.nodeName.toLowerCase()])){a=a==A?za:a;var d=a[G],f=c.cache,e=f[d];if(b){if(e){delete e[b];c.isEmptyObject(e)&&c.removeData(a)}}else{if(c.support.deleteExpando)delete a[c.expando];

else a.removeAttribute&&a.removeAttribute(c.expando);delete f[d]}}}});c.fn.extend({data:function(a,b){if(typeof a==="undefined"&&this.length)return c.data(this[0]);else if(typeof a==="object")return this.each(function(){c.data(this,a)});var d=a.split(".");d[1]=d[1]?"."+d[1]:"";if(b===w){var f=this.triggerHandler("getData"+d[1]+"!",[d[0]]);if(f===w&&this.length)f=c.data(this[0],a);return f===w&&d[1]?this.data(d[0]):f}else return this.trigger("setData"+d[1]+"!",[d[0],b]).each(function(){c.data(this,

a,b)})},removeData:function(a){return this.each(function(){c.removeData(this,a)})}});c.extend({queue:function(a,b,d){if(a){b=(b||"fx")+"queue";var f=c.data(a,b);if(!d)return f||[];if(!f||c.isArray(d))f=c.data(a,b,c.makeArray(d));else f.push(d);return f}},dequeue:function(a,b){b=b||"fx";var d=c.queue(a,b),f=d.shift();if(f==="inprogress")f=d.shift();if(f){b==="fx"&&d.unshift("inprogress");f.call(a,function(){c.dequeue(a,b)})}}});c.fn.extend({queue:function(a,b){if(typeof a!=="string"){b=a;a="fx"}if(b===

w)return c.queue(this[0],a);return this.each(function(){var d=c.queue(this,a,b);a==="fx"&&d[0]!=="inprogress"&&c.dequeue(this,a)})},dequeue:function(a){return this.each(function(){c.dequeue(this,a)})},delay:function(a,b){a=c.fx?c.fx.speeds[a]||a:a;b=b||"fx";return this.queue(b,function(){var d=this;setTimeout(function(){c.dequeue(d,b)},a)})},clearQueue:function(a){return this.queue(a||"fx",[])}});var Aa=/[\n\t]/g,ca=/\s+/,Za=/\r/g,$a=/href|src|style/,ab=/(button|input)/i,bb=/(button|input|object|select|textarea)/i,

cb=/^(a|area)$/i,Ba=/radio|checkbox/;c.fn.extend({attr:function(a,b){return X(this,a,b,true,c.attr)},removeAttr:function(a){return this.each(function(){c.attr(this,a,"");this.nodeType===1&&this.removeAttribute(a)})},addClass:function(a){if(c.isFunction(a))return this.each(function(n){var r=c(this);r.addClass(a.call(this,n,r.attr("class")))});if(a&&typeof a==="string")for(var b=(a||"").split(ca),d=0,f=this.length;d-1)return true;return false},val:function(a){if(a===w){var b=this[0];if(b){if(c.nodeName(b,"option"))return(b.attributes.value||{}).specified?b.value:b.text;if(c.nodeName(b,"select")){var d=b.selectedIndex,f=[],e=b.options;b=b.type==="select-one";if(d<0)return null;var j=b?d:0;for(d=b?d+1:e.length;j=0;else if(c.nodeName(this,"select")){var u=c.makeArray(r);c("option",this).each(function(){this.selected=

c.inArray(c(this).val(),u)>=0});if(!u.length)this.selectedIndex=-1}else this.value=r}})}});c.extend({attrFn:{val:true,css:true,html:true,text:true,data:true,width:true,height:true,offset:true},attr:function(a,b,d,f){if(!a||a.nodeType===3||a.nodeType===8)return w;if(f&&b in c.attrFn)return c(a)[b](d);f=a.nodeType!==1||!c.isXMLDoc(a);var e=d!==w;b=f&&c.props[b]||b;if(a.nodeType===1){var j=$a.test(b);if(b in a&&f&&!j){if(e){b==="type"&&ab.test(a.nodeName)&&a.parentNode&&c.error("type property can't be changed");

a[b]=d}if(c.nodeName(a,"form")&&a.getAttributeNode(b))return a.getAttributeNode(b).nodeValue;if(b==="tabIndex")return(b=a.getAttributeNode("tabIndex"))&&b.specified?b.value:bb.test(a.nodeName)||cb.test(a.nodeName)&&a.href?0:w;return a[b]}if(!c.support.style&&f&&b==="style"){if(e)a.style.cssText=""+d;return a.style.cssText}e&&a.setAttribute(b,""+d);a=!c.support.hrefNormalized&&f&&j?a.getAttribute(b,2):a.getAttribute(b);return a===null?w:a}return c.style(a,b,d)}});var O=/\.(.*)$/,db=function(a){return a.replace(/[^\w\s\.\|`]/g,

function(b){return"\\"+b})};c.event={add:function(a,b,d,f){if(!(a.nodeType===3||a.nodeType===8)){if(a.setInterval&&a!==A&&!a.frameElement)a=A;var e,j;if(d.handler){e=d;d=e.handler}if(!d.guid)d.guid=c.guid++;if(j=c.data(a)){var i=j.events=j.events||{},o=j.handle;if(!o)j.handle=o=function(){return typeof c!=="undefined"&&!c.event.triggered?c.event.handle.apply(o.elem,arguments):w};o.elem=a;b=b.split(" ");for(var k,n=0,r;k=b[n++];){j=e?c.extend({},e):{handler:d,data:f};if(k.indexOf(".")>-1){r=k.split(".");

k=r.shift();j.namespace=r.slice(0).sort().join(".")}else{r=[];j.namespace=""}j.type=k;j.guid=d.guid;var u=i[k],z=c.event.special[k]||{};if(!u){u=i[k]=[];if(!z.setup||z.setup.call(a,f,r,o)===false)if(a.addEventListener)a.addEventListener(k,o,false);else a.attachEvent&&a.attachEvent("on"+k,o)}if(z.add){z.add.call(a,j);if(!j.handler.guid)j.handler.guid=d.guid}u.push(j);c.event.global[k]=true}a=null}}},global:{},remove:function(a,b,d,f){if(!(a.nodeType===3||a.nodeType===8)){var e,j=0,i,o,k,n,r,u,z=c.data(a),

C=z&&z.events;if(z&&C){if(b&&b.type){d=b.handler;b=b.type}if(!b||typeof b==="string"&&b.charAt(0)==="."){b=b||"";for(e in C)c.event.remove(a,e+b)}else{for(b=b.split(" ");e=b[j++];){n=e;i=e.indexOf(".")<0;o=[];if(!i){o=e.split(".");e=o.shift();k=new RegExp("(^|\\.)"+c.map(o.slice(0).sort(),db).join("\\.(?:.*\\.)?")+"(\\.|$)")}if(r=C[e])if(d){n=c.event.special[e]||{};for(B=f||0;B=0){a.type=

e=e.slice(0,-1);a.exclusive=true}if(!d){a.stopPropagation();c.event.global[e]&&c.each(c.cache,function(){this.events&&this.events[e]&&c.event.trigger(a,b,this.handle.elem)})}if(!d||d.nodeType===3||d.nodeType===8)return w;a.result=w;a.target=d;b=c.makeArray(b);b.unshift(a)}a.currentTarget=d;(f=c.data(d,"handle"))&&f.apply(d,b);f=d.parentNode||d.ownerDocument;try{if(!(d&&d.nodeName&&c.noData[d.nodeName.toLowerCase()]))if(d["on"+e]&&d["on"+e].apply(d,b)===false)a.result=false}catch(j){}if(!a.isPropagationStopped()&&

f)c.event.trigger(a,b,f,true);else if(!a.isDefaultPrevented()){f=a.target;var i,o=c.nodeName(f,"a")&&e==="click",k=c.event.special[e]||{};if((!k._default||k._default.call(d,a)===false)&&!o&&!(f&&f.nodeName&&c.noData[f.nodeName.toLowerCase()])){try{if(f[e]){if(i=f["on"+e])f["on"+e]=null;c.event.triggered=true;f[e]()}}catch(n){}if(i)f["on"+e]=i;c.event.triggered=false}}},handle:function(a){var b,d,f,e;a=arguments[0]=c.event.fix(a||A.event);a.currentTarget=this;b=a.type.indexOf(".")<0&&!a.exclusive; if(!b){d=a.type.split(".");a.type=d.shift();f=new RegExp("(^|\\.)"+d.slice(0).sort().join("\\.(?:.*\\.)?")+"(\\.|$)")}e=c.data(this,"events");d=e[a.type];if(e&&d){d=d.slice(0);e=0;for(var j=d.length;e-1?c.map(a.options,function(f){return f.selected}).join("-"):"";else if(a.nodeName.toLowerCase()==="select")d=a.selectedIndex;return d},fa=function(a,b){var d=a.target,f,e;if(!(!da.test(d.nodeName)||d.readOnly)){f=c.data(d,"_change_data");e=Fa(d);if(a.type!=="focusout"||d.type!=="radio")c.data(d,"_change_data",

e);if(!(f===w||e===f))if(f!=null||e){a.type="change";return c.event.trigger(a,b,d)}}};c.event.special.change={filters:{focusout:fa,click:function(a){var b=a.target,d=b.type;if(d==="radio"||d==="checkbox"||b.nodeName.toLowerCase()==="select")return fa.call(this,a)},keydown:function(a){var b=a.target,d=b.type;if(a.keyCode===13&&b.nodeName.toLowerCase()!=="textarea"||a.keyCode===32&&(d==="checkbox"||d==="radio")||d==="select-multiple")return fa.call(this,a)},beforeactivate:function(a){a=a.target;c.data(a,

"_change_data",Fa(a))}},setup:function(){if(this.type==="file")return false;for(var a in ea)c.event.add(this,a+".specialChange",ea[a]);return da.test(this.nodeName)},teardown:function(){c.event.remove(this,".specialChange");return da.test(this.nodeName)}};ea=c.event.special.change.filters}s.addEventListener&&c.each({focus:"focusin",blur:"focusout"},function(a,b){function d(f){f=c.event.fix(f);f.type=b;return c.event.handle.call(this,f)}c.event.special[b]={setup:function(){this.addEventListener(a,

d,true)},teardown:function(){this.removeEventListener(a,d,true)}}});c.each(["bind","one"],function(a,b){c.fn[b]=function(d,f,e){if(typeof d==="object"){for(var j in d)this[b](j,f,d[j],e);return this}if(c.isFunction(f)){e=f;f=w}var i=b==="one"?c.proxy(e,function(k){c(this).unbind(k,i);return e.apply(this,arguments)}):e;if(d==="unload"&&b!=="one")this.one(d,f,e);else{j=0;for(var o=this.length;j0){y=t;break}}t=t[g]}m[q]=y}}}var f=/((?:\((?:\([^()]+\)|[^()]+)+\)|\[(?:\[[^[\]]*\]|['"][^'"]*['"]|[^[\]'"]+)+\]|\\.|[^ >+~,(\[\\]+)+|[>+~])(\s*,\s*)?((?:.|\r|\n)*)/g,

e=0,j=Object.prototype.toString,i=false,o=true;[0,0].sort(function(){o=false;return 0});var k=function(g,h,l,m){l=l||[];var q=h=h||s;if(h.nodeType!==1&&h.nodeType!==9)return[];if(!g||typeof g!=="string")return l;for(var p=[],v,t,y,S,H=true,M=x(h),I=g;(f.exec(""),v=f.exec(I))!==null;){I=v[3];p.push(v[1]);if(v[2]){S=v[3];break}}if(p.length>1&&r.exec(g))if(p.length===2&&n.relative[p[0]])t=ga(p[0]+p[1],h);else for(t=n.relative[p[0]]?[h]:k(p.shift(),h);p.length;){g=p.shift();if(n.relative[g])g+=p.shift();

t=ga(g,t)}else{if(!m&&p.length>1&&h.nodeType===9&&!M&&n.match.ID.test(p[0])&&!n.match.ID.test(p[p.length-1])){v=k.find(p.shift(),h,M);h=v.expr?k.filter(v.expr,v.set)[0]:v.set[0]}if(h){v=m?{expr:p.pop(),set:z(m)}:k.find(p.pop(),p.length===1&&(p[0]==="~"||p[0]==="+")&&h.parentNode?h.parentNode:h,M);t=v.expr?k.filter(v.expr,v.set):v.set;if(p.length>0)y=z(t);else H=false;for(;p.length;){var D=p.pop();v=D;if(n.relative[D])v=p.pop();else D="";if(v==null)v=h;n.relative[D](y,v,M)}}else y=[]}y||(y=t);y||k.error(D||

g);if(j.call(y)==="[object Array]")if(H)if(h&&h.nodeType===1)for(g=0;y[g]!=null;g++){if(y[g]&&(y[g]===true||y[g].nodeType===1&&E(h,y[g])))l.push(t[g])}else for(g=0;y[g]!=null;g++)y[g]&&y[g].nodeType===1&&l.push(t[g]);else l.push.apply(l,y);else z(y,l);if(S){k(S,q,l,m);k.uniqueSort(l)}return l};k.uniqueSort=function(g){if(B){i=o;g.sort(B);if(i)for(var h=1;h":function(g,h){var l=typeof h==="string";if(l&&!/\W/.test(h)){h=h.toLowerCase();for(var m=0,q=g.length;m=0))l||m.push(v);else if(l)h[p]=false;return false},ID:function(g){return g[1].replace(/\\/g,"")},TAG:function(g){return g[1].toLowerCase()},

CHILD:function(g){if(g[1]==="nth"){var h=/(-?)(\d*)n((?:\+|-)?\d*)/.exec(g[2]==="even"&&"2n"||g[2]==="odd"&&"2n+1"||!/\D/.test(g[2])&&"0n+"+g[2]||g[2]);g[2]=h[1]+(h[2]||1)-0;g[3]=h[3]-0}g[0]=e++;return g},ATTR:function(g,h,l,m,q,p){h=g[1].replace(/\\/g,"");if(!p&&n.attrMap[h])g[1]=n.attrMap[h];if(g[2]==="~=")g[4]=" "+g[4]+" ";return g},PSEUDO:function(g,h,l,m,q){if(g[1]==="not")if((f.exec(g[3])||"").length>1||/^\w/.test(g[3]))g[3]=k(g[3],null,null,h);else{g=k.filter(g[3],h,l,true^q);l||m.push.apply(m,

g);return false}else if(n.match.POS.test(g[0])||n.match.CHILD.test(g[0]))return true;return g},POS:function(g){g.unshift(true);return g}},filters:{enabled:function(g){return g.disabled===false&&g.type!=="hidden"},disabled:function(g){return g.disabled===true},checked:function(g){return g.checked===true},selected:function(g){return g.selected===true},parent:function(g){return!!g.firstChild},empty:function(g){return!g.firstChild},has:function(g,h,l){return!!k(l[3],g).length},header:function(g){return/h\d/i.test(g.nodeName)},

text:function(g){return"text"===g.type},radio:function(g){return"radio"===g.type},checkbox:function(g){return"checkbox"===g.type},file:function(g){return"file"===g.type},password:function(g){return"password"===g.type},submit:function(g){return"submit"===g.type},image:function(g){return"image"===g.type},reset:function(g){return"reset"===g.type},button:function(g){return"button"===g.type||g.nodeName.toLowerCase()==="button"},input:function(g){return/input|select|textarea|button/i.test(g.nodeName)}},

setFilters:{first:function(g,h){return h===0},last:function(g,h,l,m){return h===m.length-1},even:function(g,h){return h%2===0},odd:function(g,h){return h%2===1},lt:function(g,h,l){return hl[3]-0},nth:function(g,h,l){return l[3]-0===h},eq:function(g,h,l){return l[3]-0===h}},filter:{PSEUDO:function(g,h,l,m){var q=h[1],p=n.filters[q];if(p)return p(g,l,h,m);else if(q==="contains")return(g.textContent||g.innerText||a([g])||"").indexOf(h[3])>=0;else if(q==="not"){h=

h[3];l=0;for(m=h.length;l=0}},ID:function(g,h){return g.nodeType===1&&g.getAttribute("id")===h},TAG:function(g,h){return h==="*"&&g.nodeType===1||g.nodeName.toLowerCase()===h},CLASS:function(g,h){return(" "+(g.className||g.getAttribute("class"))+" ").indexOf(h)>-1},ATTR:function(g,h){var l=h[1];g=n.attrHandle[l]?n.attrHandle[l](g):g[l]!=null?g[l]:g.getAttribute(l);l=g+"";var m=h[2];h=h[4];return g==null?m==="!=":m===

"="?l===h:m==="*="?l.indexOf(h)>=0:m==="~="?(" "+l+" ").indexOf(h)>=0:!h?l&&g!==false:m==="!="?l!==h:m==="^="?l.indexOf(h)===0:m==="$="?l.substr(l.length-h.length)===h:m==="|="?l===h||l.substr(0,h.length+1)===h+"-":false},POS:function(g,h,l,m){var q=n.setFilters[h[2]];if(q)return q(g,l,h,m)}}},r=n.match.POS;for(var u in n.match){n.match[u]=new RegExp(n.match[u].source+/(?![^\[]*\])(?![^\(]*\))/.source);n.leftMatch[u]=new RegExp(/(^(?:.|\r|\n)*?)/.source+n.match[u].source.replace(/\\(\d+)/g,function(g,

h){return"\\"+(h-0+1)}))}var z=function(g,h){g=Array.prototype.slice.call(g,0);if(h){h.push.apply(h,g);return h}return g};try{Array.prototype.slice.call(s.documentElement.childNodes,0)}catch(C){z=function(g,h){h=h||[];if(j.call(g)==="[object Array]")Array.prototype.push.apply(h,g);else if(typeof g.length==="number")for(var l=0,m=g.length;l";var l=s.documentElement;l.insertBefore(g,l.firstChild);if(s.getElementById(h)){n.find.ID=function(m,q,p){if(typeof q.getElementById!=="undefined"&&!p)return(q=q.getElementById(m[1]))?q.id===m[1]||typeof q.getAttributeNode!=="undefined"&&

q.getAttributeNode("id").nodeValue===m[1]?[q]:w:[]};n.filter.ID=function(m,q){var p=typeof m.getAttributeNode!=="undefined"&&m.getAttributeNode("id");return m.nodeType===1&&p&&p.nodeValue===q}}l.removeChild(g);l=g=null})();(function(){var g=s.createElement("div");g.appendChild(s.createComment(""));if(g.getElementsByTagName("*").length>0)n.find.TAG=function(h,l){l=l.getElementsByTagName(h[1]);if(h[1]==="*"){h=[];for(var m=0;l[m];m++)l[m].nodeType===1&&h.push(l[m]);l=h}return l};g.innerHTML="";

if(g.firstChild&&typeof g.firstChild.getAttribute!=="undefined"&&g.firstChild.getAttribute("href")!=="#")n.attrHandle.href=function(h){return h.getAttribute("href",2)};g=null})();s.querySelectorAll&&function(){var g=k,h=s.createElement("div");h.innerHTML="

";if(!(h.querySelectorAll&&h.querySelectorAll(".TEST").length===0)){k=function(m,q,p,v){q=q||s;if(!v&&q.nodeType===9&&!x(q))try{return z(q.querySelectorAll(m),p)}catch(t){}return g(m,q,p,v)};for(var l in g)k[l]=g[l];h=null}}();

(function(){var g=s.createElement("div");g.innerHTML="

";if(!(!g.getElementsByClassName||g.getElementsByClassName("e").length===0)){g.lastChild.className="e";if(g.getElementsByClassName("e").length!==1){n.order.splice(1,0,"CLASS");n.find.CLASS=function(h,l,m){if(typeof l.getElementsByClassName!=="undefined"&&!m)return l.getElementsByClassName(h[1])};g=null}}})();var E=s.compareDocumentPosition?function(g,h){return!!(g.compareDocumentPosition(h)&16)}:

function(g,h){return g!==h&&(g.contains?g.contains(h):true)},x=function(g){return(g=(g?g.ownerDocument||g:0).documentElement)?g.nodeName!=="HTML":false},ga=function(g,h){var l=[],m="",q;for(h=h.nodeType?[h]:h;q=n.match.PSEUDO.exec(g);){m+=q[0];g=g.replace(n.match.PSEUDO,"")}g=n.relative[g]?g+"*":g;q=0;for(var p=h.length;q=0===d})};c.fn.extend({find:function(a){for(var b=this.pushStack("","find",a),d=0,f=0,e=this.length;f0)for(var j=d;j0},closest:function(a,b){if(c.isArray(a)){var d=[],f=this[0],e,j=

{},i;if(f&&a.length){e=0;for(var o=a.length;e-1:c(f).is(e)){d.push({selector:i,elem:f});delete j[i]}}f=f.parentNode}}return d}var k=c.expr.match.POS.test(a)?c(a,b||this.context):null;return this.map(function(n,r){for(;r&&r.ownerDocument&&r!==b;){if(k?k.index(r)>-1:c(r).is(a))return r;r=r.parentNode}return null})},index:function(a){if(!a||typeof a===

"string")return c.inArray(this[0],a?c(a):this.parent().children());return c.inArray(a.jquery?a[0]:a,this)},add:function(a,b){a=typeof a==="string"?c(a,b||this.context):c.makeArray(a);b=c.merge(this.get(),a);return this.pushStack(qa(a[0])||qa(b[0])?b:c.unique(b))},andSelf:function(){return this.add(this.prevObject)}});c.each({parent:function(a){return(a=a.parentNode)&&a.nodeType!==11?a:null},parents:function(a){return c.dir(a,"parentNode")},parentsUntil:function(a,b,d){return c.dir(a,"parentNode",

d)},next:function(a){return c.nth(a,2,"nextSibling")},prev:function(a){return c.nth(a,2,"previousSibling")},nextAll:function(a){return c.dir(a,"nextSibling")},prevAll:function(a){return c.dir(a,"previousSibling")},nextUntil:function(a,b,d){return c.dir(a,"nextSibling",d)},prevUntil:function(a,b,d){return c.dir(a,"previousSibling",d)},siblings:function(a){return c.sibling(a.parentNode.firstChild,a)},children:function(a){return c.sibling(a.firstChild)},contents:function(a){return c.nodeName(a,"iframe")?

a.contentDocument||a.contentWindow.document:c.makeArray(a.childNodes)}},function(a,b){c.fn[a]=function(d,f){var e=c.map(this,b,d);eb.test(a)||(f=d);if(f&&typeof f==="string")e=c.filter(f,e);e=this.length>1?c.unique(e):e;if((this.length>1||gb.test(f))&&fb.test(a))e=e.reverse();return this.pushStack(e,a,R.call(arguments).join(","))}});c.extend({filter:function(a,b,d){if(d)a=":not("+a+")";return c.find.matches(a,b)},dir:function(a,b,d){var f=[];for(a=a[b];a&&a.nodeType!==9&&(d===w||a.nodeType!==1||!c(a).is(d));){a.nodeType===

1&&f.push(a);a=a[b]}return f},nth:function(a,b,d){b=b||1;for(var f=0;a;a=a[d])if(a.nodeType===1&&++f===b)break;return a},sibling:function(a,b){for(var d=[];a;a=a.nextSibling)a.nodeType===1&&a!==b&&d.push(a);return d}});var Ja=/ jQuery\d+="(?:\d+|null)"/g,V=/^\s+/,Ka=/(<([\w:]+)[^>]*?)\/>/g,hb=/^(?:area|br|col|embed|hr|img|input|link|meta|param)$/i,La=/<([\w:]+)/,ib=/"},F={option:[1,""],legend:[1,"

"],thead:[1,"

"],tr:[2,"

"],td:[3,"

"],col:[2,"

"],area:[1,"

"],_default:[0,"",""]};F.optgroup=F.option;F.tbody=F.tfoot=F.colgroup=F.caption=F.thead;F.th=F.td;if(!c.support.htmlSerialize)F._default=[1,"div

","

"];c.fn.extend({text:function(a){if(c.isFunction(a))return this.each(function(b){var d=

c(this);d.text(a.call(this,b,d.text()))});if(typeof a!=="object"&&a!==w)return this.empty().append((this[0]&&this[0].ownerDocument||s).createTextNode(a));return c.text(this)},wrapAll:function(a){if(c.isFunction(a))return this.each(function(d){c(this).wrapAll(a.call(this,d))});if(this[0]){var b=c(a,this[0].ownerDocument).eq(0).clone(true);this[0].parentNode&&b.insertBefore(this[0]);b.map(function(){for(var d=this;d.firstChild&&d.firstChild.nodeType===1;)d=d.firstChild;return d}).append(this)}return this},

wrapInner:function(a){if(c.isFunction(a))return this.each(function(b){c(this).wrapInner(a.call(this,b))});return this.each(function(){var b=c(this),d=b.contents();d.length?d.wrapAll(a):b.append(a)})},wrap:function(a){return this.each(function(){c(this).wrapAll(a)})},unwrap:function(){return this.parent().each(function(){c.nodeName(this,"body")||c(this).replaceWith(this.childNodes)}).end()},append:function(){return this.domManip(arguments,true,function(a){this.nodeType===1&&this.appendChild(a)})},

prepend:function(){return this.domManip(arguments,true,function(a){this.nodeType===1&&this.insertBefore(a,this.firstChild)})},before:function(){if(this[0]&&this[0].parentNode)return this.domManip(arguments,false,function(b){this.parentNode.insertBefore(b,this)});else if(arguments.length){var a=c(arguments[0]);a.push.apply(a,this.toArray());return this.pushStack(a,"before",arguments)}},after:function(){if(this[0]&&this[0].parentNode)return this.domManip(arguments,false,function(b){this.parentNode.insertBefore(b,

this.nextSibling)});else if(arguments.length){var a=this.pushStack(this,"after",arguments);a.push.apply(a,c(arguments[0]).toArray());return a}},remove:function(a,b){for(var d=0,f;(f=this[d])!=null;d++)if(!a||c.filter(a,[f]).length){if(!b&&f.nodeType===1){c.cleanData(f.getElementsByTagName("*"));c.cleanData([f])}f.parentNode&&f.parentNode.removeChild(f)}return this},empty:function(){for(var a=0,b;(b=this[a])!=null;a++)for(b.nodeType===1&&c.cleanData(b.getElementsByTagName("*"));b.firstChild;)b.removeChild(b.firstChild);

return this},clone:function(a){var b=this.map(function(){if(!c.support.noCloneEvent&&!c.isXMLDoc(this)){var d=this.outerHTML,f=this.ownerDocument;if(!d){d=f.createElement("div");d.appendChild(this.cloneNode(true));d=d.innerHTML}return c.clean([d.replace(Ja,"").replace(/=([^="'>\s]+\/)>/g,'="$1">').replace(V,"")],f)[0]}else return this.cloneNode(true)});if(a===true){ra(this,b);ra(this.find("*"),b.find("*"))}return b},html:function(a){if(a===w)return this[0]&&this[0].nodeType===1?this[0].innerHTML.replace(Ja,

""):null;else if(typeof a==="string"&&!ta.test(a)&&(c.support.leadingWhitespace||!V.test(a))&&!F[(La.exec(a)||["",""])[1].toLowerCase()]){a=a.replace(Ka,Ma);try{for(var b=0,d=this.length;b0||e.cacheable||this.length>1?k.cloneNode(true):k)}o.length&&c.each(o,Qa)}return this}});c.fragments={};c.each({appendTo:"append",prependTo:"prepend",insertBefore:"before",insertAfter:"after",replaceAll:"replaceWith"},function(a,b){c.fn[a]=function(d){var f=[];d=c(d);var e=this.length===1&&this[0].parentNode;if(e&&e.nodeType===11&&e.childNodes.length===1&&d.length===1){d[b](this[0]);

return this}else{e=0;for(var j=d.length;e0?this.clone(true):this).get();c.fn[b].apply(c(d[e]),i);f=f.concat(i)}return this.pushStack(f,a,d.selector)}}});c.extend({clean:function(a,b,d,f){b=b||s;if(typeof b.createElement==="undefined")b=b.ownerDocument||b[0]&&b[0].ownerDocument||s;for(var e=[],j=0,i;(i=a[j])!=null;j++){if(typeof i==="number")i+="";if(i){if(typeof i==="string"&&!jb.test(i))i=b.createTextNode(i);else if(typeof i==="string"){i=i.replace(Ka,Ma);var o=(La.exec(i)||["",

""])[1].toLowerCase(),k=F[o]||F._default,n=k[0],r=b.createElement("div");for(r.innerHTML=k[1]+i+k[2];n--;)r=r.lastChild;if(!c.support.tbody){n=ib.test(i);o=o==="table"&&!n?r.firstChild&&r.firstChild.childNodes:k[1]==="

"&&!n?r.childNodes:[];for(k=o.length-1;k>=0;--k)c.nodeName(o[k],"tbody")&&!o[k].childNodes.length&&o[k].parentNode.removeChild(o[k])}!c.support.leadingWhitespace&&V.test(i)&&r.insertBefore(b.createTextNode(V.exec(i)[0]),r.firstChild);i=r.childNodes}if(i.nodeType)e.push(i);else e=

c.merge(e,i)}}if(d)for(j=0;e[j];j++)if(f&&c.nodeName(e[j],"script")&&(!e[j].type||e[j].type.toLowerCase()==="text/javascript"))f.push(e[j].parentNode?e[j].parentNode.removeChild(e[j]):e[j]);else{e[j].nodeType===1&&e.splice.apply(e,[j+1,0].concat(c.makeArray(e[j].getElementsByTagName("script"))));d.appendChild(e[j])}return e},cleanData:function(a){for(var b,d,f=c.cache,e=c.event.special,j=c.support.deleteExpando,i=0,o;(o=a[i])!=null;i++)if(d=o[c.expando]){b=f[d];if(b.events)for(var k in b.events)e[k]?

c.event.remove(o,k):Ca(o,k,b.handle);if(j)delete o[c.expando];else o.removeAttribute&&o.removeAttribute(c.expando);delete f[d]}}});var kb=/z-?index|font-?weight|opacity|zoom|line-?height/i,Na=/alpha\([^)]*\)/,Oa=/opacity=([^)]*)/,ha=/float/i,ia=/-([a-z])/ig,lb=/([A-Z])/g,mb=/^-?\d+(?:px)?$/i,nb=/^-?\d/,ob={position:"absolute",visibility:"hidden",display:"block"},pb=["Left","Right"],qb=["Top","Bottom"],rb=s.defaultView&&s.defaultView.getComputedStyle,Pa=c.support.cssFloat?"cssFloat":"styleFloat",ja=

function(a,b){return b.toUpperCase()};c.fn.css=function(a,b){return X(this,a,b,true,function(d,f,e){if(e===w)return c.curCSS(d,f);if(typeof e==="number"&&!kb.test(f))e+="px";c.style(d,f,e)})};c.extend({style:function(a,b,d){if(!a||a.nodeType===3||a.nodeType===8)return w;if((b==="width"||b==="height")&&parseFloat(d)<0)d=w;var f=a.style||a,e=d!==w;if(!c.support.opacity&&b==="opacity"){if(e){f.zoom=1;b=parseInt(d,10)+""==="NaN"?"":"alpha(opacity="+d*100+")";a=f.filter||c.curCSS(a,"filter")||"";f.filter= Na.test(a)?a.replace(Na,b):b}return f.filter&&f.filter.indexOf("opacity=")>=0?parseFloat(Oa.exec(f.filter)[1])/100+"":""}if(ha.test(b))b=Pa;b=b.replace(ia,ja);if(e)f[b]=d;return f[b]},css:function(a,b,d,f){if(b==="width"||b==="height"){var e,j=b==="width"?pb:qb;function i(){e=b==="width"?a.offsetWidth:a.offsetHeight;f!=="border"&&c.each(j,function(){f||(e-=parseFloat(c.curCSS(a,"padding"+this,true))||0);if(f==="margin")e+=parseFloat(c.curCSS(a,"margin"+this,true))||0;else e-=parseFloat(c.curCSS(a,

"border"+this+"Width",true))||0})}a.offsetWidth!==0?i():c.swap(a,ob,i);return Math.max(0,Math.round(e))}return c.curCSS(a,b,d)},curCSS:function(a,b,d){var f,e=a.style;if(!c.support.opacity&&b==="opacity"&&a.currentStyle){f=Oa.test(a.currentStyle.filter||"")?parseFloat(RegExp.$1)/100+"":"";return f===""?"1":f}if(ha.test(b))b=Pa;if(!d&&e&&e[b])f=e[b];else if(rb){if(ha.test(b))b="float";b=b.replace(lb,"-$1").toLowerCase();e=a.ownerDocument.defaultView;if(!e)return null;if(a=e.getComputedStyle(a,null))f=

a.getPropertyValue(b);if(b==="opacity"&&f==="")f="1"}else if(a.currentStyle){d=b.replace(ia,ja);f=a.currentStyle[b]||a.currentStyle[d];if(!mb.test(f)&&nb.test(f)){b=e.left;var j=a.runtimeStyle.left;a.runtimeStyle.left=a.currentStyle.left;e.left=d==="fontSize"?"1em":f||0;f=e.pixelLeft+"px";e.left=b;a.runtimeStyle.left=j}}return f},swap:function(a,b,d){var f={};for(var e in b){f[e]=a.style[e];a.style[e]=b[e]}d.call(a);for(e in b)a.style[e]=f[e]}});if(c.expr&&c.expr.filters){c.expr.filters.hidden=function(a){var b=

a.offsetWidth,d=a.offsetHeight,f=a.nodeName.toLowerCase()==="tr";return b===0&&d===0&&!f?true:b>0&&d>0&&!f?false:c.curCSS(a,"display")==="none"};c.expr.filters.visible=function(a){return!c.expr.filters.hidden(a)}}var sb=J(),tb=//gi,ub=/select|textarea/i,vb=/color|date|datetime|email|hidden|month|number|password|range|search|tel|text|time|url|week/i,N=/=\?(&|$)/,ka=/\?/,wb=/(\?|&)_=.*?(&|$)/,xb=/^(\w+:)?\/\/([^\/?#]+)/,yb=/%20/g,zb=c.fn.load;c.fn.extend({load:function(a,b,d){if(typeof a!==

"string")return zb.call(this,a);else if(!this.length)return this;var f=a.indexOf(" ");if(f>=0){var e=a.slice(f,a.length);a=a.slice(0,f)}f="GET";if(b)if(c.isFunction(b)){d=b;b=null}else if(typeof b==="object"){b=c.param(b,c.ajaxSettings.traditional);f="POST"}var j=this;c.ajax({url:a,type:f,dataType:"html",data:b,complete:function(i,o){if(o==="success"||o==="notmodified")j.html(e?c("

").append(i.responseText.replace(tb,"")).find(e):i.responseText);d&&j.each(d,[i.responseText,o,i])}});return this},

serialize:function(){return c.param(this.serializeArray())},serializeArray:function(){return this.map(function(){return this.elements?c.makeArray(this.elements):this}).filter(function(){return this.name&&!this.disabled&&(this.checked||ub.test(this.nodeName)||vb.test(this.type))}).map(function(a,b){a=c(this).val();return a==null?null:c.isArray(a)?c.map(a,function(d){return{name:b.name,value:d}}):{name:b.name,value:a}}).get()}});c.each("ajaxStart ajaxStop ajaxComplete ajaxError ajaxSuccess ajaxSend".split(" "),

function(a,b){c.fn[b]=function(d){return this.bind(b,d)}});c.extend({get:function(a,b,d,f){if(c.isFunction(b)){f=f||d;d=b;b=null}return c.ajax({type:"GET",url:a,data:b,success:d,dataType:f})},getScript:function(a,b){return c.get(a,null,b,"script")},getJSON:function(a,b,d){return c.get(a,b,d,"json")},post:function(a,b,d,f){if(c.isFunction(b)){f=f||d;d=b;b={}}return c.ajax({type:"POST",url:a,data:b,success:d,dataType:f})},ajaxSetup:function(a){c.extend(c.ajaxSettings,a)},ajaxSettings:{url:location.href,

global:true,type:"GET",contentType:"application/x-www-form-urlencoded",processData:true,async:true,xhr:A.XMLHttpRequest&&(A.location.protocol!=="file:"||!A.ActiveXObject)?function(){return new A.XMLHttpRequest}:function(){try{return new A.ActiveXObject("Microsoft.XMLHTTP")}catch(a){}},accepts:{xml:"application/xml, text/xml",html:"text/html",script:"text/javascript, application/javascript",json:"application/json, text/javascript",text:"text/plain",_default:"*/*"}},lastModified:{},etag:{},ajax:function(a){function b(){e.success&&

e.success.call(k,o,i,x);e.global&&f("ajaxSuccess",[x,e])}function d(){e.complete&&e.complete.call(k,x,i);e.global&&f("ajaxComplete",[x,e]);e.global&&!--c.active&&c.event.trigger("ajaxStop")}function f(q,p){(e.context?c(e.context):c.event).trigger(q,p)}var e=c.extend(true,{},c.ajaxSettings,a),j,i,o,k=a&&a.context||e,n=e.type.toUpperCase();if(e.data&&e.processData&&typeof e.data!=="string")e.data=c.param(e.data,e.traditional);if(e.dataType==="jsonp"){if(n==="GET")N.test(e.url)||(e.url+=(ka.test(e.url)?

"&":"?")+(e.jsonp||"callback")+"=?");else if(!e.data||!N.test(e.data))e.data=(e.data?e.data+"&":"")+(e.jsonp||"callback")+"=?";e.dataType="json"}if(e.dataType==="json"&&(e.data&&N.test(e.data)||N.test(e.url))){j=e.jsonpCallback||"jsonp"+sb++;if(e.data)e.data=(e.data+"").replace(N,"="+j+"$1");e.url=e.url.replace(N,"="+j+"$1");e.dataType="script";A[j]=A[j]||function(q){o=q;b();d();A[j]=w;try{delete A[j]}catch(p){}z&&z.removeChild(C)}}if(e.dataType==="script"&&e.cache===null)e.cache=false;if(e.cache===

false&&n==="GET"){var r=J(),u=e.url.replace(wb,"$1_="+r+"$2");e.url=u+(u===e.url?(ka.test(e.url)?"&":"?")+"_="+r:"")}if(e.data&&n==="GET")e.url+=(ka.test(e.url)?"&":"?")+e.data;e.global&&!c.active++&&c.event.trigger("ajaxStart");r=(r=xb.exec(e.url))&&(r[1]&&r[1]!==location.protocol||r[2]!==location.host);if(e.dataType==="script"&&n==="GET"&&r){var z=s.getElementsByTagName("head")[0]||s.documentElement,C=s.createElement("script");C.src=e.url;if(e.scriptCharset)C.charset=e.scriptCharset;if(!j){var B=

false;C.onload=C.onreadystatechange=function(){if(!B&&(!this.readyState||this.readyState==="loaded"||this.readyState==="complete")){B=true;b();d();C.onload=C.onreadystatechange=null;z&&C.parentNode&&z.removeChild(C)}}}z.insertBefore(C,z.firstChild);return w}var E=false,x=e.xhr();if(x){e.username?x.open(n,e.url,e.async,e.username,e.password):x.open(n,e.url,e.async);try{if(e.data||a&&a.contentType)x.setRequestHeader("Content-Type",e.contentType);if(e.ifModified){c.lastModified[e.url]&&x.setRequestHeader("If-Modified-Since",

c.lastModified[e.url]);c.etag[e.url]&&x.setRequestHeader("If-None-Match",c.etag[e.url])}r||x.setRequestHeader("X-Requested-With","XMLHttpRequest");x.setRequestHeader("Accept",e.dataType&&e.accepts[e.dataType]?e.accepts[e.dataType]+", */*":e.accepts._default)}catch(ga){}if(e.beforeSend&&e.beforeSend.call(k,x,e)===false){e.global&&!--c.active&&c.event.trigger("ajaxStop");x.abort();return false}e.global&&f("ajaxSend",[x,e]);var g=x.onreadystatechange=function(q){if(!x||x.readyState===0||q==="abort"){E||

d();E=true;if(x)x.onreadystatechange=c.noop}else if(!E&&x&&(x.readyState===4||q==="timeout")){E=true;x.onreadystatechange=c.noop;i=q==="timeout"?"timeout":!c.httpSuccess(x)?"error":e.ifModified&&c.httpNotModified(x,e.url)?"notmodified":"success";var p;if(i==="success")try{o=c.httpData(x,e.dataType,e)}catch(v){i="parsererror";p=v}if(i==="success"||i==="notmodified")j||b();else c.handleError(e,x,i,p);d();q==="timeout"&&x.abort();if(e.async)x=null}};try{var h=x.abort;x.abort=function(){x&&h.call(x);

g("abort")}}catch(l){}e.async&&e.timeout>0&&setTimeout(function(){x&&!E&&g("timeout")},e.timeout);try{x.send(n==="POST"||n==="PUT"||n==="DELETE"?e.data:null)}catch(m){c.handleError(e,x,null,m);d()}e.async||g();return x}},handleError:function(a,b,d,f){if(a.error)a.error.call(a.context||a,b,d,f);if(a.global)(a.context?c(a.context):c.event).trigger("ajaxError",[b,a,f])},active:0,httpSuccess:function(a){try{return!a.status&&location.protocol==="file:"||a.status>=200&&a.status<300||a.status===304||a.status=== 1223||a.status===0}catch(b){}return false},httpNotModified:function(a,b){var d=a.getResponseHeader("Last-Modified"),f=a.getResponseHeader("Etag");if(d)c.lastModified[b]=d;if(f)c.etag[b]=f;return a.status===304||a.status===0},httpData:function(a,b,d){var f=a.getResponseHeader("content-type")||"",e=b==="xml"||!b&&f.indexOf("xml")>=0;a=e?a.responseXML:a.responseText;e&&a.documentElement.nodeName==="parsererror"&&c.error("parsererror");if(d&&d.dataFilter)a=d.dataFilter(a,b);if(typeof a==="string")if(b===

"json"||!b&&f.indexOf("json")>=0)a=c.parseJSON(a);else if(b==="script"||!b&&f.indexOf("javascript")>=0)c.globalEval(a);return a},param:function(a,b){function d(i,o){if(c.isArray(o))c.each(o,function(k,n){b||/\[\]$/.test(i)?f(i,n):d(i+"["+(typeof n==="object"||c.isArray(n)?k:"")+"]",n)});else!b&&o!=null&&typeof o==="object"?c.each(o,function(k,n){d(i+"["+k+"]",n)}):f(i,o)}function f(i,o){o=c.isFunction(o)?o():o;e[e.length]=encodeURIComponent(i)+"="+encodeURIComponent(o)}var e=[];if(b===w)b=c.ajaxSettings.traditional;

if(c.isArray(a)||a.jquery)c.each(a,function(){f(this.name,this.value)});else for(var j in a)d(j,a[j]);return e.join("&").replace(yb,"+")}});var la={},Ab=/toggle|show|hide/,Bb=/^([+-]=)?([\d+-.]+)(.*)$/,W,va=[["height","marginTop","marginBottom","paddingTop","paddingBottom"],["width","marginLeft","marginRight","paddingLeft","paddingRight"],["opacity"]];c.fn.extend({show:function(a,b){if(a||a===0)return this.animate(K("show",3),a,b);else{a=0;for(b=this.length;a").appendTo("body");f=e.css("display");if(f==="none")f="block";e.remove();la[d]=f}c.data(this[a],"olddisplay",f)}}a=0;for(b=this.length;a=0;f--)if(d[f].elem===this){b&&d[f](true);d.splice(f,1)}});b||this.dequeue();return this}});c.each({slideDown:K("show",1),slideUp:K("hide",1),slideToggle:K("toggle",1),fadeIn:{opacity:"show"},fadeOut:{opacity:"hide"}},function(a,b){c.fn[a]=function(d,f){return this.animate(b,d,f)}});c.extend({speed:function(a,b,d){var f=a&&typeof a==="object"?a:{complete:d||!d&&b||c.isFunction(a)&&a,duration:a,easing:d&&b||b&&!c.isFunction(b)&&b};f.duration=c.fx.off?0:typeof f.duration===

"number"?f.duration:c.fx.speeds[f.duration]||c.fx.speeds._default;f.old=f.complete;f.complete=function(){f.queue!==false&&c(this).dequeue();c.isFunction(f.old)&&f.old.call(this)};return f},easing:{linear:function(a,b,d,f){return d+f*a},swing:function(a,b,d,f){return(-Math.cos(a*Math.PI)/2+0.5)*f+d}},timers:[],fx:function(a,b,d){this.options=b;this.elem=a;this.prop=d;if(!b.orig)b.orig={}}});c.fx.prototype={update:function(){this.options.step&&this.options.step.call(this.elem,this.now,this);(c.fx.step[this.prop]||

c.fx.step._default)(this);if((this.prop==="height"||this.prop==="width")&&this.elem.style)this.elem.style.display="block"},cur:function(a){if(this.elem[this.prop]!=null&&(!this.elem.style||this.elem.style[this.prop]==null))return this.elem[this.prop];return(a=parseFloat(c.css(this.elem,this.prop,a)))&&a>-10000?a:parseFloat(c.curCSS(this.elem,this.prop))||0},custom:function(a,b,d){function f(j){return e.step(j)}this.startTime=J();this.start=a;this.end=b;this.unit=d||this.unit||"px";this.now=this.start;

this.pos=this.state=0;var e=this;f.elem=this.elem;if(f()&&c.timers.push(f)&&!W)W=setInterval(c.fx.tick,13)},show:function(){this.options.orig[this.prop]=c.style(this.elem,this.prop);this.options.show=true;this.custom(this.prop==="width"||this.prop==="height"?1:0,this.cur());c(this.elem).show()},hide:function(){this.options.orig[this.prop]=c.style(this.elem,this.prop);this.options.hide=true;this.custom(this.cur(),0)},step:function(a){var b=J(),d=true;if(a||b>=this.options.duration+this.startTime){this.now=

this.end;this.pos=this.state=1;this.update();this.options.curAnim[this.prop]=true;for(var f in this.options.curAnim)if(this.options.curAnim[f]!==true)d=false;if(d){if(this.options.display!=null){this.elem.style.overflow=this.options.overflow;a=c.data(this.elem,"olddisplay");this.elem.style.display=a?a:this.options.display;if(c.css(this.elem,"display")==="none")this.elem.style.display="block"}this.options.hide&&c(this.elem).hide();if(this.options.hide||this.options.show)for(var e in this.options.curAnim)c.style(this.elem,

e,this.options.orig[e]);this.options.complete.call(this.elem)}return false}else{e=b-this.startTime;this.state=e/this.options.duration;a=this.options.easing||(c.easing.swing?"swing":"linear");this.pos=c.easing[this.options.specialEasing&&this.options.specialEasing[this.prop]||a](this.state,e,0,1,this.options.duration);this.now=this.start+(this.end-this.start)*this.pos;this.update()}return true}};c.extend(c.fx,{tick:function(){for(var a=c.timers,b=0;b

";

a.insertBefore(b,a.firstChild);d=b.firstChild;f=d.firstChild;e=d.nextSibling.firstChild.firstChild;this.doesNotAddBorder=f.offsetTop!==5;this.doesAddBorderForTableAndCells=e.offsetTop===5;f.style.position="fixed";f.style.top="20px";this.supportsFixedPosition=f.offsetTop===20||f.offsetTop===15;f.style.position=f.style.top="";d.style.overflow="hidden";d.style.position="relative";this.subtractsBorderForOverflowNotVisible=f.offsetTop===-5;this.doesNotIncludeMarginInBodyOffset=a.offsetTop!==j;a.removeChild(b);

c.offset.initialize=c.noop},bodyOffset:function(a){var b=a.offsetTop,d=a.offsetLeft;c.offset.initialize();if(c.offset.doesNotIncludeMarginInBodyOffset){b+=parseFloat(c.curCSS(a,"marginTop",true))||0;d+=parseFloat(c.curCSS(a,"marginLeft",true))||0}return{top:b,left:d}},setOffset:function(a,b,d){if(/static/.test(c.curCSS(a,"position")))a.style.position="relative";var f=c(a),e=f.offset(),j=parseInt(c.curCSS(a,"top",true),10)||0,i=parseInt(c.curCSS(a,"left",true),10)||0;if(c.isFunction(b))b=b.call(a,

d,e);d={top:b.top-e.top+j,left:b.left-e.left+i};"using"in b?b.using.call(a,d):f.css(d)}};c.fn.extend({position:function(){if(!this[0])return null;var a=this[0],b=this.offsetParent(),d=this.offset(),f=/^body|html$/i.test(b[0].nodeName)?{top:0,left:0}:b.offset();d.top-=parseFloat(c.curCSS(a,"marginTop",true))||0;d.left-=parseFloat(c.curCSS(a,"marginLeft",true))||0;f.top+=parseFloat(c.curCSS(b[0],"borderTopWidth",true))||0;f.left+=parseFloat(c.curCSS(b[0],"borderLeftWidth",true))||0;return{top:d.top-

f.top,left:d.left-f.left}},offsetParent:function(){return this.map(function(){for(var a=this.offsetParent||s.body;a&&!/^body|html$/i.test(a.nodeName)&&c.css(a,"position")==="static";)a=a.offsetParent;return a})}});c.each(["Left","Top"],function(a,b){var d="scroll"+b;c.fn[d]=function(f){var e=this[0],j;if(!e)return null;if(f!==w)return this.each(function(){if(j=wa(this))j.scrollTo(!a?f:c(j).scrollLeft(),a?f:c(j).scrollTop());else this[d]=f});else return(j=wa(e))?"pageXOffset"in j?j[a?"pageYOffset":

"pageXOffset"]:c.support.boxModel&&j.document.documentElement[d]||j.document.body[d]:e[d]}});c.each(["Height","Width"],function(a,b){var d=b.toLowerCase();c.fn["inner"+b]=function(){return this[0]?c.css(this[0],d,false,"padding"):null};c.fn["outer"+b]=function(f){return this[0]?c.css(this[0],d,false,f?"margin":"border"):null};c.fn[d]=function(f){var e=this[0];if(!e)return f==null?null:this;if(c.isFunction(f))return this.each(function(j){var i=c(this);i[d](f.call(this,j,i[d]()))});return"scrollTo"in

e&&e.document?e.document.compatMode==="CSS1Compat"&&e.document.documentElement["client"+b]||e.document.body["client"+b]:e.nodeType===9?Math.max(e.documentElement["client"+b],e.body["scroll"+b],e.documentElement["scroll"+b],e.body["offset"+b],e.documentElement["offset"+b]):f===w?c.css(e,d):this.css(d,typeof f==="string"?f:f+"px")}});A.jQuery=A.$=c})(window);

Contact us

Telephone:(852) 2838 3620

Email:sales@silverwing.com.hk

Address: Unit 2, 4/F, Kwai Cheong Centre, 50 Kwai Cheong Road, Kwai Chung, New Territories, Hong Kong

What is the use of isolation voltage 3000VDC in the power module?

Source:

Time:2018-10-12 12:08:23

views:

With the rapid development of the microelectronics industry, the electromagnetic environment for product use is becoming more and more complex, and the stability of the product is also greatly affected. Embedded product manufacturers add various isolation devices or isolation circuits to reduce interference at the job site and enhance device stability.

As the energy supply part of the embedded device, the power supply is the prerequisite for stable operation of the product. The isolation of the power supply is especially important, and the application of the power isolation module has become a must for embedded device design. In industrial equipment, power isolation between two devices is required. A DC converter with a transformer is used to separate the two power supplies so that they are independent of each other, thereby reducing external interference!

一、Introduction of isolated withstand voltage and creepage distance of isolated power supply

1. Isolation withstand voltage of isolated power supply

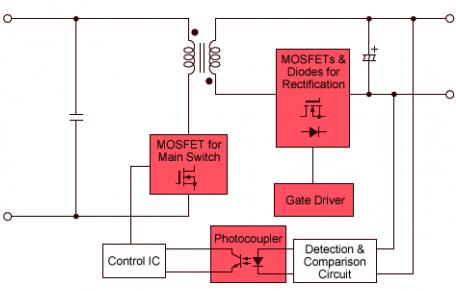

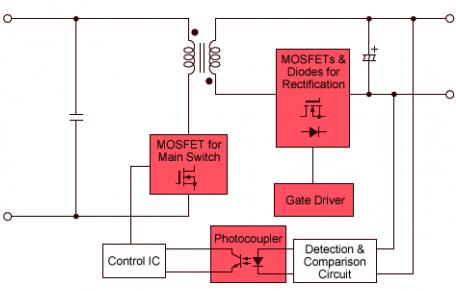

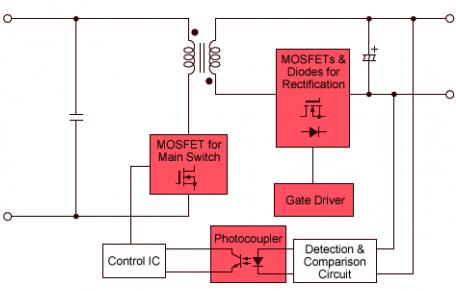

Figure 1 Internal block diagram of isolated power supply

As shown in Figure 1, isolate the internal block diagram of the DC-DC power module. Isolation withstand voltage refers to the highest insulation voltage that two systems without direct electrical connections can withstand. Power isolation is used differently, and the corresponding parameter selection is not used. Such as: AD-DC power supply isolation, general industrial requirements require isolation pressure between 3000VAC to 4000VAC; DC-DC power isolation in general industrial applications require 1000VDC to 2000VDC, special industries may be high, the medical industry has requirements 6000VDC.

First, distinguish the units of each voltage indicator, common ADC, VAC and RMS, as shown below.

VAC/VDC refers to AC voltage and DC voltage respectively, but AC and DC in isolation withstand voltage cannot be easily converted. For example, the amplitude voltage of 3000VAC is 4242V, but in practical applications, the isolation withstand voltage 3000VAC is not equivalent to 4242VDC. . The specific reasons include two points. First, for the isolation module, there is an isolation capacitor between the input and output. For the DC signal, the impedance of the capacitor is infinite, so the size of the isolation capacitor does not have much influence on the DC signal, but for the AC signal. There will be a greater impact, the leakage current will become larger, or directly exceed the standard, the system alarms. Second, another difference between AC and DC is that the frequency affects the dielectric constant of the dielectric. The frequency causes the dielectric constant of the dielectric to decrease. Generally, the higher the dielectric constant, the stronger the insulation.

RMS refers to the true rms value, which simply means that the alternating current is equivalent to the work done by the direct current in unit time. That is, the AC with a true rms value of 10V is the same as the 10V DC for the same load at the same time. This unit is usually not used as a unit of measurement for isolation withstand voltage.

2、isolated power creepage distance introduction

How to ensure the stability and safety of isolation withstand voltage, to ensure that the isolated power module is not broken down, we have to calculate the creepage distance. The distance between the two conductive members, or one of the conductive members and the device and the accessible surface, measured along the surface of the insulating material, the distance along which the insulating surface is discharged, that is, the distance of the creepage, also known as the creepage distance, the creepage distance = the surface distance / The highest voltage of the system, depending on the degree of contamination.

Figure 1 Internal block diagram of isolated power supply

As shown in Figure 1, isolate the internal block diagram of the DC-DC power module. Isolation withstand voltage refers to the highest insulation voltage that two systems without direct electrical connections can withstand. Power isolation is used differently, and the corresponding parameter selection is not used. Such as: AD-DC power supply isolation, general industrial requirements require isolation pressure between 3000VAC to 4000VAC; DC-DC power isolation in general industrial applications require 1000VDC to 2000VDC, special industries may be high, the medical industry has requirements 6000VDC.

First, distinguish the units of each voltage indicator, common ADC, VAC and RMS, as shown below.

VAC/VDC refers to AC voltage and DC voltage respectively, but AC and DC in isolation withstand voltage cannot be easily converted. For example, the amplitude voltage of 3000VAC is 4242V, but in practical applications, the isolation withstand voltage 3000VAC is not equivalent to 4242VDC. . The specific reasons include two points. First, for the isolation module, there is an isolation capacitor between the input and output. For the DC signal, the impedance of the capacitor is infinite, so the size of the isolation capacitor does not have much influence on the DC signal, but for the AC signal. There will be a greater impact, the leakage current will become larger, or directly exceed the standard, the system alarms. Second, another difference between AC and DC is that the frequency affects the dielectric constant of the dielectric. The frequency causes the dielectric constant of the dielectric to decrease. Generally, the higher the dielectric constant, the stronger the insulation.

RMS refers to the true rms value, which simply means that the alternating current is equivalent to the work done by the direct current in unit time. That is, the AC with a true rms value of 10V is the same as the 10V DC for the same load at the same time. This unit is usually not used as a unit of measurement for isolation withstand voltage.

2、isolated power creepage distance introduction

How to ensure the stability and safety of isolation withstand voltage, to ensure that the isolated power module is not broken down, we have to calculate the creepage distance. The distance between the two conductive members, or one of the conductive members and the device and the accessible surface, measured along the surface of the insulating material, the distance along which the insulating surface is discharged, that is, the distance of the creepage, also known as the creepage distance, the creepage distance = the surface distance / The highest voltage of the system, depending on the degree of contamination.

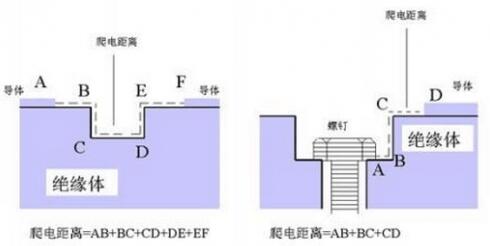

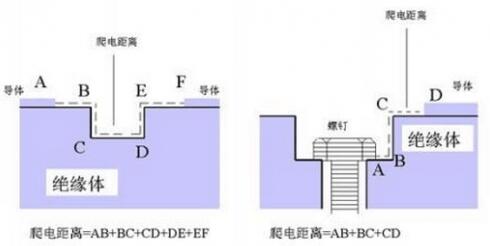

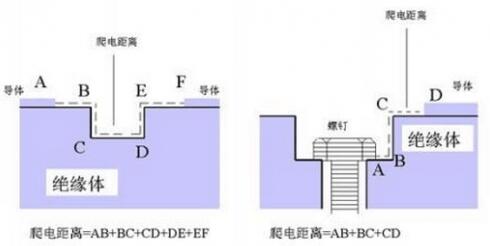

Figure 2 Schematic diagram of creepage distance

In the IEC60950 and GB4943-2011 standards, the minimum safety distance required for different voltage levels is specified, and the safety distance includes both electrical spacing and creepage distance. There are two aspects to the place where the switching power supply mainly needs to ensure the minimum safe distance:

1. The safety distance of the primary side circuit to the outer casing (protected ground);

2. The safety distance between the primary side circuit and the secondary side circuit.

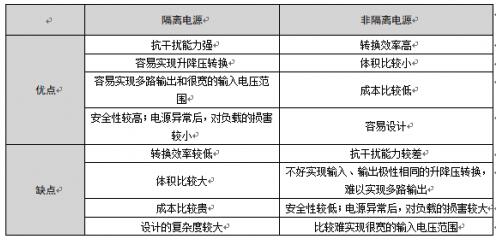

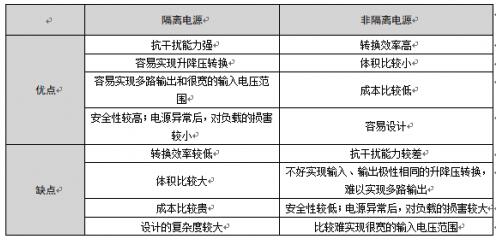

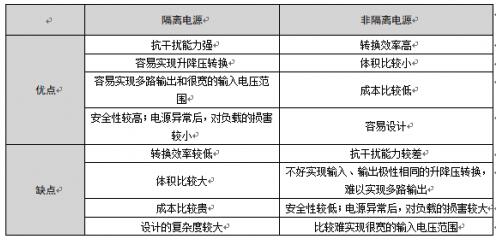

The advantages and disadvantages of isolated power compared to non-isolated power are shown in Figure 3.

Figure 2 Schematic diagram of creepage distance

In the IEC60950 and GB4943-2011 standards, the minimum safety distance required for different voltage levels is specified, and the safety distance includes both electrical spacing and creepage distance. There are two aspects to the place where the switching power supply mainly needs to ensure the minimum safe distance:

1. The safety distance of the primary side circuit to the outer casing (protected ground);

2. The safety distance between the primary side circuit and the secondary side circuit.

The advantages and disadvantages of isolated power compared to non-isolated power are shown in Figure 3.

Figure 3 Comparison of isolated and non-isolated power supplies

二、the application of isolated power

In the application of embedded products, various interferences will threaten the stability of the product. In the product design stage, the isolated power supply module and the isolated communication module are selected to effectively shield the interference caused by the use environment and stabilize the product. Work brings security. We often see some mobile phone charging explosions in the media, news reports of electric shock when the phone is charging. Isolating the Advance Enery power module is a good way to ensure the stability of the product and, more importantly, to protect the user's life and property. Isolated power supplies are currently used in two ways. The devices are built separately and use DC-DC power modules, as shown below.

1, program selection

After the product performance requirements are clear, then the next step is to start designing and development. The first thing to do is to select the circuit scheme. Here are some common "negative materials". For example, design and development of a mains AC input to DC output, many people think of the first time to use the power frequency conversion circuit program, because this program is relatively simple, a power frequency transformer, plus a rectification filter can be done, as follows Figure 4 shows. Products using this solution are very inefficient, and the size of the product is very large, and the application is accompanied by a very troublesome power frequency eddy current. The module solution uses a suitable transformer, and multiple process layers ensure the product consistency of the transformer and ensure the final performance of the product.

Figure 3 Comparison of isolated and non-isolated power supplies

二、the application of isolated power

In the application of embedded products, various interferences will threaten the stability of the product. In the product design stage, the isolated power supply module and the isolated communication module are selected to effectively shield the interference caused by the use environment and stabilize the product. Work brings security. We often see some mobile phone charging explosions in the media, news reports of electric shock when the phone is charging. Isolating the Advance Enery power module is a good way to ensure the stability of the product and, more importantly, to protect the user's life and property. Isolated power supplies are currently used in two ways. The devices are built separately and use DC-DC power modules, as shown below.

1, program selection

After the product performance requirements are clear, then the next step is to start designing and development. The first thing to do is to select the circuit scheme. Here are some common "negative materials". For example, design and development of a mains AC input to DC output, many people think of the first time to use the power frequency conversion circuit program, because this program is relatively simple, a power frequency transformer, plus a rectification filter can be done, as follows Figure 4 shows. Products using this solution are very inefficient, and the size of the product is very large, and the application is accompanied by a very troublesome power frequency eddy current. The module solution uses a suitable transformer, and multiple process layers ensure the product consistency of the transformer and ensure the final performance of the product.

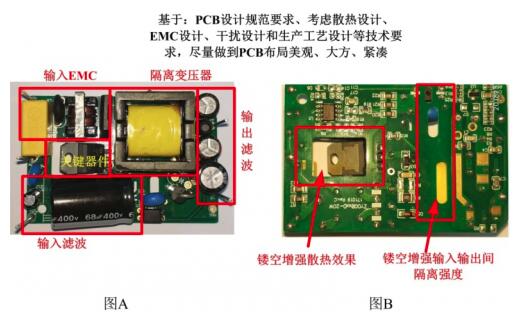

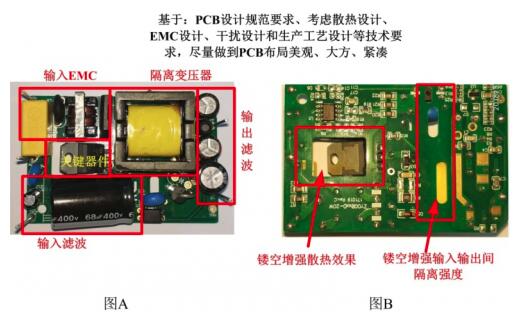

Figure 4 Comparison of transformer solutions

2. Material selection and PCB design

After the circuit scheme is determined, the next step is to design the product performance parameters. The parameter design, calculation and structural material selection of the electronic components in the circuit scheme must be weighed in many aspects.

First, the selection of materials. In the professional module power supply manufacturers can do both, according to the different specifications of the product, different application conditions, to eliminate the unnecessary material specifications, select the optimal material specifications.

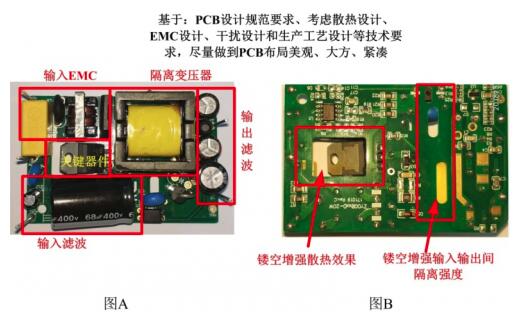

Second, the design of the PCB of the power module. Because the module power supply product has the PCB design specification requirements of the module power supply, it should consider the heat dissipation design, EMC design, interference design and production process design, etc., and the content involved is not large, so the PCB design is used as the module power product development process. One of the most important aspects to treat, as shown in Figure 5.

Figure 4 Comparison of transformer solutions

2. Material selection and PCB design

After the circuit scheme is determined, the next step is to design the product performance parameters. The parameter design, calculation and structural material selection of the electronic components in the circuit scheme must be weighed in many aspects.

First, the selection of materials. In the professional module power supply manufacturers can do both, according to the different specifications of the product, different application conditions, to eliminate the unnecessary material specifications, select the optimal material specifications.

Second, the design of the PCB of the power module. Because the module power supply product has the PCB design specification requirements of the module power supply, it should consider the heat dissipation design, EMC design, interference design and production process design, etc., and the content involved is not large, so the PCB design is used as the module power product development process. One of the most important aspects to treat, as shown in Figure 5.

Figure 5 PCB design requirements

Compared with the traditional design, Yinwei Electronic Constant Voltage Series Isolated Power Module adopts the best solution in the industry from topology, chip solution to components, with higher integration and reliability, and can provide user I/O and communication. Applications such as isolation provide a standard, reliable solution.

Figure 5 PCB design requirements

Compared with the traditional design, Yinwei Electronic Constant Voltage Series Isolated Power Module adopts the best solution in the industry from topology, chip solution to components, with higher integration and reliability, and can provide user I/O and communication. Applications such as isolation provide a standard, reliable solution.