air flow

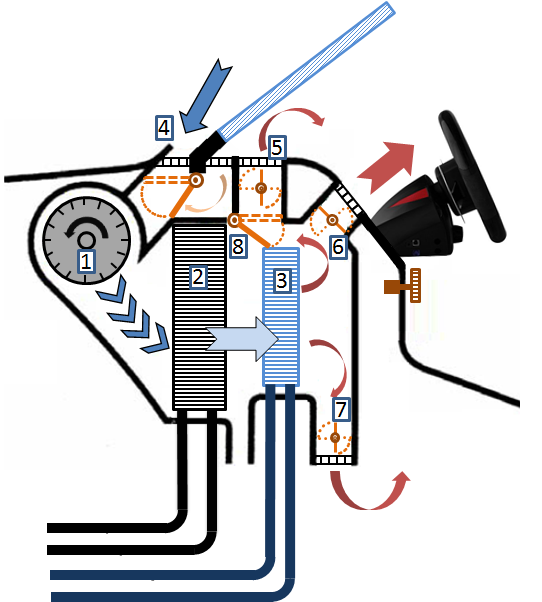

Regardless of the type of vehicle, the automotive HVAC system exchanges air and changes its temperature, humidity, and quality during the process. Let's take a look at the principle of air flow. Air can be sucked into the system from outside or inside the cabin. It can also be adjusted by entering the HVAC system through an evaporator or heat exchanger; the air is distributed throughout the cabin, keeping the passenger's feet warm and preventing the windshield from misting. There are many ways in which air flows: from the outside to the evaporator to the windshield, or from the inside to the heat exchanger to the vent at the bottom of the compartment. So how does the HVAC system control the flow of air?

Figure 1 is a side view of an HVAC system. The key components are marked with numbers and the arrows indicate the direction of air flow. Components 4 to 8 in FIG. 1 show damper actuators. The orange dotted line indicates the area where the damper moves, and the solid orange line indicates the damper. The number of damper actuators in an HVAC system depends on the overall complexity of the system - whether it is a single-zone or multi-zone HVAC.

Figure 1: Automotive HVAC consisting of eight components: 1 = blower, 2 = evaporator, 3 = heater, 4 = intake damper, 5, 6 and 7 = air distribution damper, 8 = air mixing damper

Actuator

There are three types of damper actuators in automotive HVAC systems:

Intake damper actuator (component 4 in Figure 1): This damper actuator controls the regulation of air source - off-board air or recirculation air in the vehicle. The damper actuator position may be controlled by the driver using a recirculation button or by the HVAC system based on data from the in-vehicle air quality sensor.

Air mixing damper actuator (part 8 in Fig. 1): The damper actuator mixes heating (heat exchanger) and cold air (evaporator) to reach the set air temperature.

Air Distribution Throttle Actuators (Parts 5, 6 and 7 in Fig. 1): The number of damper actuators of this type differs depending on the type of vehicle and is used to distribute the air in the compartment.

DC

Which electrical equipment is responsible for driving the damper? Just as there are many ways to control the flow of air, car manufacturers also have a variety of options for driving the damper's electrical equipment. Includes a brushed DC motor with a potentiometer for sensing the position of the damper; a three-phase brushless DC (BLDC) motor using a back-EMF (back-EMF) measurement position or a stepper motor that measures the position by calculating the number of steps. ITW Switch These DC motors drive the damper through different sized gears.

More choices

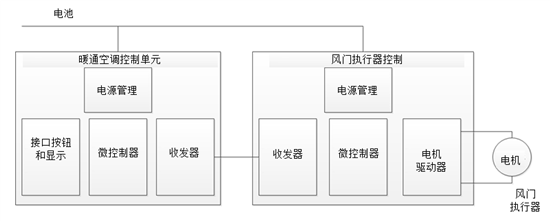

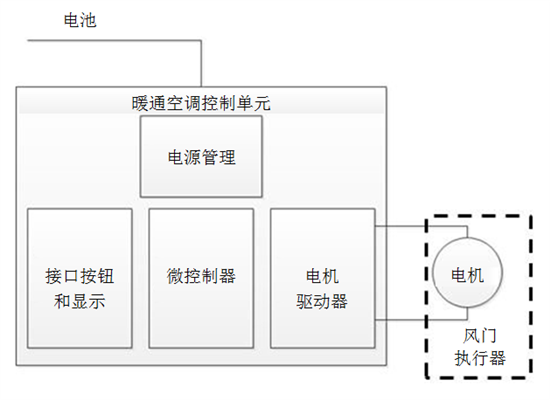

After selecting the motor, the HVAC system engineer can also choose to drive the motor's architecture. As mentioned earlier, the damper actuator can be controlled locally or remotely. In the local control, the electronic device controlling the motor is located near the motor, ie, the motor control IC is integrated in the same housing where the motor is located (see the damper actuator control in FIG. 2 ). A communications protocol such as a local area interconnect network (LIN) controls the motor to drive the damper to a specific location. In remote control, the electronic equipment that controls the motor is located in the HVAC control unit away from the damper actuator (see Figure 3). The communication between the motor driver and the microcontroller on the HVAC control unit can be achieved via a serial peripheral interface (SPI), even through a parallel digital control interface.

Figures 2 and 3 illustrate two possible architectures. The architecture in Figure 2 is more complex than the architecture in Figure 3; however, the architecture in Figure 2 provides greater design scalability and flexibility.

Figure 1: Remote control of the damper actuator motor

Figure 3: Integrated motor drive of the damper actuator

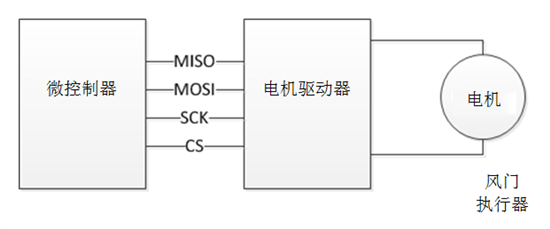

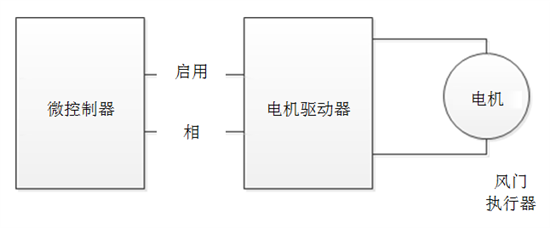

Let's take a look at the connection between the microcontroller and the motor driver control IC. HVAC system designers also have many options for this connection. The microcontroller can be connected to the motor driver using a digital communication interface (such as SPI), or it can be directly connected to the motor driver using a control line. Figures 4 and 5 illustrate these options.

Figure 4: Microcontroller communicating with motor driver using SPI

Figure 5: Microcontroller with Direct Control of Motor Drivers

Simplified components

Drive electronics for BLDC and stepper motors are more complex than the electronics needed to drive brushed DC motors. If you choose to use a brushed DC motor to move the damper, the use of a motor driver that directly drives the damper motor has clear advantages - both in terms of hardware and software.