Buildings, plant equipment, vehicles, warehouses, pallets and workers themselves are increasingly connected to the network, ranging from tiny environmental sensors to complex industrial robots. The networks they use may be wired or wireless, and some low-power devices will use battery-powered or Ethernet-powered (PoE) connections, and others must be plugged into or connected to the building's electrical system. Many devices have their own firmware that can be remotely updated or reprogrammed.

In other words, sensors, controllers, and specialized devices now exist at the edge of the network, assigning unique IP or network addresses, collecting data, and performing tasks that involve a large number of notifications and extend enterprise capabilities. This is the Industrial Networking (IIoT), which will change the manufacturing, transportation, construction, mining and energy industries.

What is intelligent manufacturing

The development of intelligent manufacturing has gone through three stages: the artificial intelligence has been applied in the field of manufacturing in the 1980s. The concept of intelligent manufacturing technology and intelligent manufacturing system has been put forward in the 1990s. "Intelligent manufacturing under the new generation of information technology in the 21st century "Began to form. Smart manufacturing is defined as "modeling the skills and expertise of manufacturing technicians by integrating knowledge engineering, manufacturing software systems, robot vision and robot control to enable intelligent machines to perform small batch production without human intervention " Look at these nine scenes, you will be on the industrial Internet and intelligent manufacturing more understanding.

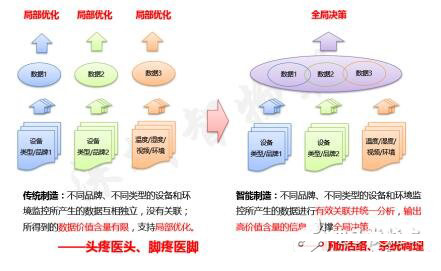

1、 equipment and environmental data collection - from single to global

Scene: how many brands of a factory, many types of production equipment need networking, and real-time monitoring, good trouble ah ... ...

A brand, B brand, C brand ... ... equipment data and environmental data were collected and uploaded to a different database; different brands of equipment data standards are not unified, all the equipment data and environmental data is not associated, can only do a single point Analysis, and can not do the overall data analysis.

To achieve the normalization of the data standards, making the A brand, B brand, C brand ... ... equipment data and temperature, humidity, air quality, voltage, current ... ... and other environmental data collected and uploaded to the same database. Can be in the same database for all the equipment to run data and environmental data for the overall analysis.

Scene: a car assembly plant has hundreds of processes, the daily output is 1,000 cars, can ensure 365 days without trouble?

Monitor the operation of the equipment, passively determine whether each process is "normal" or "faulty", and any one process failure, the entire pipeline have to stop production. Please the manufacturers of the process of home repair equipment at least 2 days or more, the loss of 1,000 cars a day profit.

Intelligent manufacturing model

The equipment to run the data analysis and comparison, in advance to predict the equipment may occur, invite the relevant manufacturers of maintenance personnel to replace the door, arrange a 2-hour active shutdown, the failure to minimize losses.

3、reduce product maintenance costs and operational risk

Scene: a boiler manufacturing enterprises need to factory factory boilers regularly maintenance, how to control maintenance costs?

Traditional manufacturing model

Manual inspection, the cost is getting higher and higher. Boiler operation data is lost and can not be optimized

Intelligent manufacturing model

Will be all the operating data of the boiler back to the original, can be targeted to arrange inspection, greatly reduce the cost of after-sales service; boiler operation data analysis and operation optimization, to extend the boiler life and reduce risk.

4、 enterprise transformation and upgrading: from the manufacturer to the operation of service providers

Scene: In 2005, GE's aircraft engine company changed its name to "GE Aviation", a major business model transformation.

Traditional manufacturing model

Before the transition: only the engine products.

Intelligent manufacturing model

After the transformation: to provide aviation management services, including the operation and maintenance management, capacity assurance, operational optimization and financial planning of the entire solution, but also can provide security controls, flight control, scheduling optimization, flight information forecasting and other services, The value of the control is greater;

Effect: the past is the plane after landing in the maintenance, and now can be in the flight of the engine can be real-time monitoring of the health of the aircraft after landing can be timely maintenance. Now fly from Chicago to Shanghai flight, landing only after 3 hours to be able to check from Shanghai to return to Chicago, the airport turnover rate greatly improved.

5、to ensure that spare parts sales: an important source of profits

Scenario: The profits of the main equipment sales are getting lower and lower, and the sales of spare parts become an important source of profit for a company.

Traditional manufacturing model

Can not monitor the sales of equipment and components of the operating state, the user may use the "cottage manufacturers" production of spare parts, not only cause production risks, will also affect the original spare parts sales.

Intelligent manufacturing model

Able to monitor the operation of remote devices and components in real time, ahead of schedule spare parts sales and user docking. Can be timely detection of "cottage products" and the application of the corresponding counter-means.

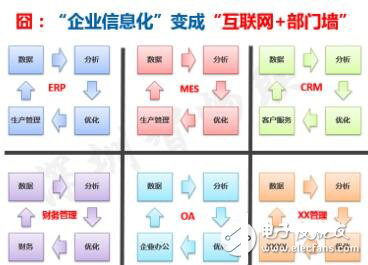

6、enterprise information: from the data island to the real business large data

Scene: a business invested a lot of manpower, material and financial resources, carried out the "information construction."

Traditional manufacturing model

Enterprises on the MES, ERP, CRM, OA, financial management and many other management systems. But the data between these systems did not get through, forming a one of the "data island", "enterprise information" reduced to "Internet + sector wall." And to open up these data is a more vast project, in particular, is not conducive to the overall decision to do industrial semiconductor companies.

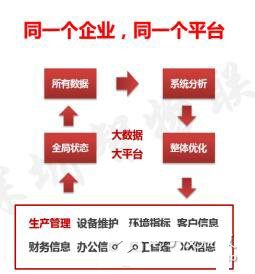

Intelligent manufacturing model

(Including, but not limited to, manufacturing, resource management, equipment status, environment, energy consumption, finance, logistics, warehousing, personnel management, suppliers, customer relations), and all the data involved in the operation of the enterprise. All uploaded to the same database, according to the needs of the overall business decision from the integration of the database at any time to call the data analysis.

7、large industrial data and large data analysis: from data to value

Scene: All data for a manufacturing company has been uploaded to the data center / cloud, but is that enough?

Traditional manufacturing model

The lack of logic between the data, there is no appropriate analytical tools, "big data" into a "dead data", can not produce any value. 90% of the world's largest data engineers are wasting data on invalid data.

Intelligent manufacturing model

According to the needs of manufacturing-oriented enterprises to establish the relationship between the data and logic, such as the establishment of "equipment energy consumption - ambient temperature", "production - warehousing - logistics" data correlation model to facilitate enterprise production optimization and decision - making.

8、 business investment decision-making: from blind investment to chapter to follow

Scenario: The company's total investment next year, there are 50 million, need to use a lot of money, how to balance the demands of various departments?

Traditional manufacturing model

There is no data analysis and support, easy to form a "racking their brains" blind investment, AE power and even the various departments and corporate decision-making between the "private relations" to become one of the factors affecting investment (will call the child have milk to eat) And once the investment mistakes may result in full disk are lost.

Intelligent manufacturing model

As a result of all the previous data are recorded and analyzed, the establishment of a market demand - production - logistics - warehousing - supply chain - human resources and other data between the dynamic correlation model, making every investment can be rules to follow, not Disregard.

9、 industrial artificial intelligence: business operations and automatic optimization, auxiliary decision-making

Traditional manufacturing model

Enterprise data collection more and more, by the human brain has been unable to conduct a reasonable data analysis, if the boss / business executives need to be responsible for all the decisions, they often seem powerless, so more and more believe that "luck."

Intelligent manufacturing model

The accumulation of data for enterprise operations allows industrial artificial intelligence robots to learn, and gradually to the standardization, process of production and management optimization by industrial AI robot to complete. Boss / business executives can focus on strategic decisions.

10、Shenzhen Silver Granville Electronic Technology Co., Ltd.'s core strengths

In the technology products, product market and specific market projects and customer service process, the Silver Granville Group has accumulated a wealth of practical experience in combat. Silverway Group has formed a "technology - product - application - service - feedback - technology" closed - loop, to achieve the continuous optimization of products and technologies.