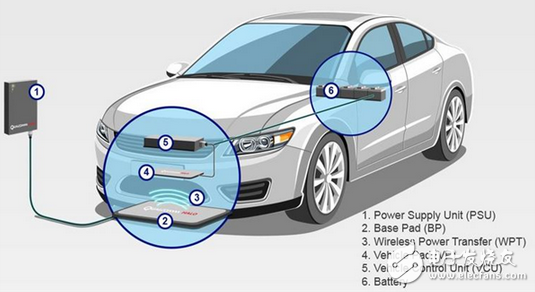

一、the system composition

Electric car wireless charging WPC system, basically by the power box, ground launch pad, car receiver board, car controller composed of four parts. The current wireless charging WPC is mainly one-way Grid to Vehicle (G2V) power supply, after the inevitable development of two-way power supply, that is, G2V + V2G. For convenience, this article is still referred to as "ground launcher" and "car receiving board".

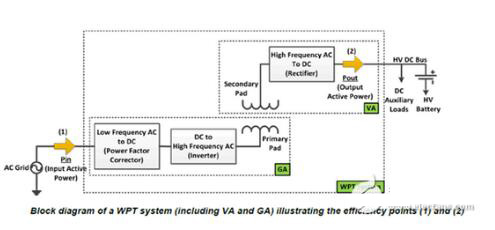

GA-Ground Assembly, ground launch pad; VA-Vehicle Assemble, the car receiver board. Wireless charging WPC is a weak coupling system, the coupling coefficient k ≈ 0.1-0.4. Nominal operating frequency of 85kHz, the frequency range of 81.38-90kHz.

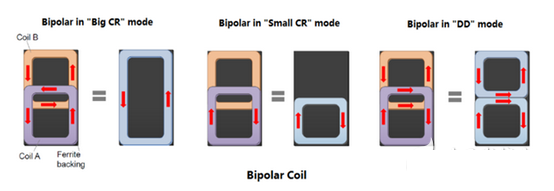

二、the coil structure

In the wireless charging WPC system, the common coil structure CR, DD, and multi-coil (such as Bipolar). CR structure is a single ring structure, can be rounded into a circular, oval, or square; DD structure is actually a Liz line from one coil to another coil; and Bipolar is composed of two separate coil part of the overlap The

Compared to the traditional CR structure, DD structure is smaller, lighter, more efficient, low sensitivity, interoperability better.

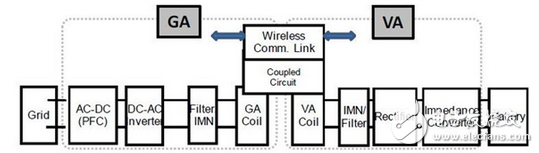

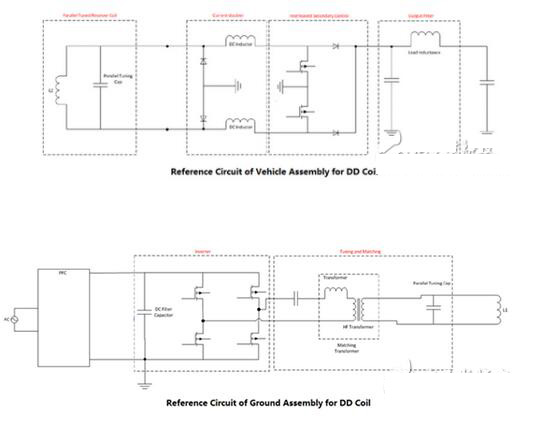

三、the circuit topology

What kind of circuit selection topology, and the coil structure, power level, gap gap and other design requirements. Different manufacturers have their own unique design, and some involve patented technology and intellectual property rights. Here are two typical examples:

四、power and efficiency

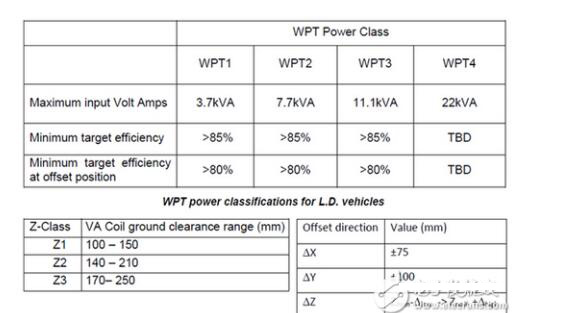

WPT (Wireless Power Transfer) system can be divided into different power levels. SAE J2954 TIR, IEC 61980 PT, and GB GB of the draft are different. The above criteria are not officially released, the following content from SAE J2954 TIR.

Standard requirements in the maximum input power, the system efficiency is higher than 85%; in the left and right deviation of ± 100mm, before and after the deviation of ± 75mm, Of the circumstances, not less than 80%. Please note that this is the efficiency of the whole system from the AC input (1) to the DC output (2).

Efficiency is a very complex concept, the brother that at least with the following factors: 1, the location of the center, that is, X, Y direction of the position deviation, but the median position is not always the highest point of efficiency; 2, Or lower than the nominal value, the system efficiency will be reduced; 3, the position of the corner, that is, the relative three-dimensional axis of the body angle deviation, the greater the deviation, the lower the efficiency; 4, the output power, in general, with the output power 5, the working temperature, poor design of the system fever is serious, only derating work, so boot after a period of time after the efficiency of the decline; 6, life stage, with the service time, Electronic components will be aging, the parameters drift, if the system automatically adjust the capacity will also affect the system efficiency. 7, test methods, we all know the importance of test methods, methods are not difficult to convincing the test results. The The The The The So, say, talk about the conditions of the so-called test conditions are playing rogue! Some people set up a system, measured the measured as if the efficiency is also good, so they declared their high efficiency products up to 90% efficiency. Currently, there are only two solutions on the market for wireless charging WPC, TI and IDT. The Amotech ASC-504060E00-S00, RX power coil has been consulted in the IDT P9221-R Wireless Receiver 15W Wireless Charger product. This is a popular item in the mobile phone market, Samsung's new S8 is using IDT and Amotech, if you are choosing IDT chipset can contact our company colleagues.

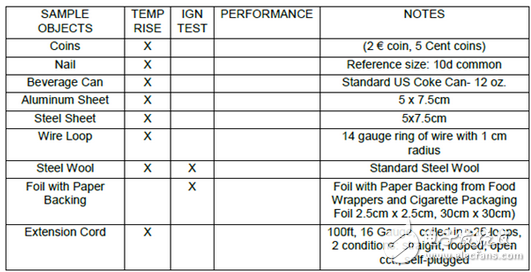

五、foreign body detection

The metal objects in the alternating magnetic field are heated due to the vortex thermal effect or hysteresis loss. If the temperature is too high, in some extreme cases will ignite the combustor near the charge plate. Therefore, foreign body detection is concerned with product safety and is particularly important. Many manufacturers claim that their products have foreign body detection function, but the specific performance is not yet known. Common metal foreign bodies are:

The foreign body detection module is usually installed in the ground launcher. Outside the main coil, a matrix type detection coil is arranged. When a metal foreign body falls on the launch pad, it will cause a change in the magnetic field of the corresponding area, and this changing magnetic field will be detected. For very small metal objects, such as paper on the book set, this method is generally difficult to detect, only by limiting the magnetic induction strength to ensure safety. Under the same power conditions, DD-shaped coil compared to the CR-shaped coil magnetic induction strength is low, so the security is also higher.

六、 living protection

We are more worried about the wireless charging WPC system of electromagnetic radiation, because the electromagnetic waves can not see touch. In the area between the charging plate and the receiving plate, the magnetic field strength is the largest. In order to prevent small animals, such as cats, dogs, etc., due to long-term exposure to high-intensity electromagnetic field caused by tissue damage, and some manufacturers to develop live protection. When the small animals close to the charging board, the system detects and stops charging; once the small animals leave, the system can restore the charging function.

七、positioning function

The smaller the position deviation of the wireless charging WPC system, the higher the system performance. Commonly used methods are MV (MagneTIc Vector) and LPE (Low Power ExcitaTIon). MV is the use of several sets of auxiliary coil through the magnetic field detection to achieve, VA on the X / Y two sets of auxiliary coil issued 120-140kHz electromagnetic waves, GA on the three groups of X / Y / Z coil used to detect the signal, the theoretical scope of work Up to 5m. LPE is a multiplexed power coil to achieve the positioning function, transmitted by the GA, VA reception, the working range of less than 1m. Compared to MV mode, LPE precision is low, but the cost is superior.

八、 interoperability

Interoperability not only requires different types of coils can match between normal, but also requires different power levels, different ground clearance of the wireless charging system can be backward compatible. Standards have the corresponding provisions.

九、 EMC (Electromagnetic Compatibility)

As with any other automotive electronics, the wireless charging WPC system complies with the Vehicle Level and Component Level EMC requirements.