一、3D glass market big

OLED screen to promote

OLED screen with a flexible, flexible features, need to meet the 3D glass paste show advantages. With the maturity of OLED technology and the application of a number of mobile phone manufacturers, 3D glass will usher in a major market outbreak.

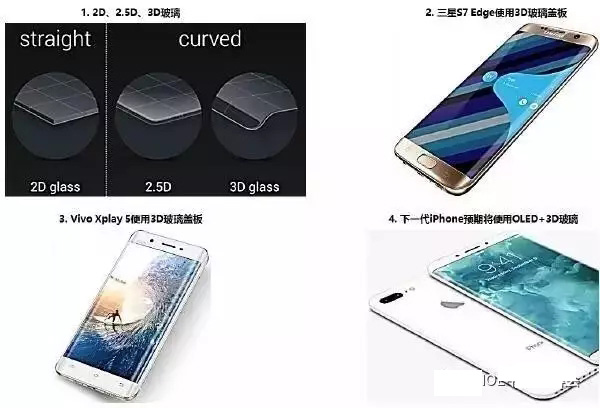

3D glass gradually become the standard in the high-end mobile phone

The need for wireless charging technology

Sony, Nokia, Google, Motorola, Samsung's wireless charging program

The metal has the electromagnetic shielding characteristics, electromagnetic waves can not be well through the metal chassis, energy loss, not suitable for wireless charging technology applications, non-metallic materials, 3D glass has become the best choice.

Higher value

Metal shell with electromagnetic shielding, which affects the 4G mobile phone communication signal, so the need for metal shell is divided into multi-segment, in order to ensure the quality of communication. This is more and more focus on "value" of the smart phone market, limiting the brand manufacturers to shape the appearance of differentiated space. While the glass material can be very good to avoid this problem.

Comparison of metal chassis and glass backplane

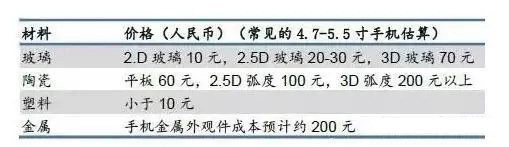

Cost advantage

Glass compared to other mobile phone backplane material, but also has a greater cost advantage, and the manufacturing process gradually mature, the yield is also rising.

Mobile phone backplane four kinds of materials (glass, ceramics, plastic, metal) cost comparison

二、3D glass processing equipment overview

Technological innovation drives equipment updates

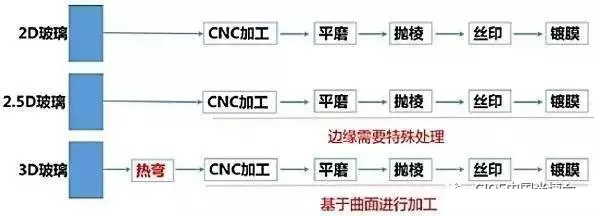

3D glass production process compared to 2D, 2.5D glass has four difficulties, surface molding, surface polishing, surface printing, surface fit.

3D surface glass production process of the four major process challenges

2D, 2.5D, 3D glass production process difference

In recent years, with the technological innovation of processing equipment is also constantly upgrading, such as high-speed multi-line cutting machine to replace the traditional cutting equipment, carved machine to replace the traditional profiling machine, double-sided copper plate grinding machine, High-speed polishing machine to become an urgent need for grinding (polishing) machine-specific equipment.

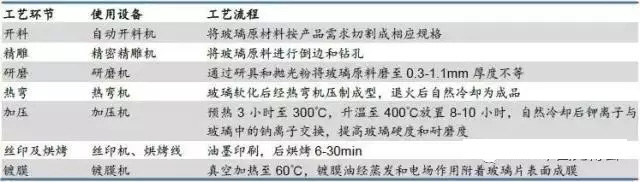

Analysis of 3D Surface Glass Production Process Equipment and Operation

Roving machine: machine design and graphite mold is the focus

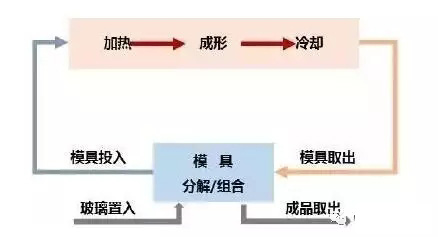

Hot bending process

The machine design determines the quality of the machine. 11 station equipment, for example, 1-4 station is the preheating station, the temperature of the glass placed in the first four stations to ensure that the flatness within 5; the middle of the three stations are forming stations, the end of the bending , The glass has been pressed into the surface of the glass, forming station to ensure that the flatness within the 4; behind 4 stations is the cooling station to ensure that the flatness within 5. If the flatness difference is too high, do the glass will appear asymmetric, bending, deformation and other issues.

Using different number of workstations

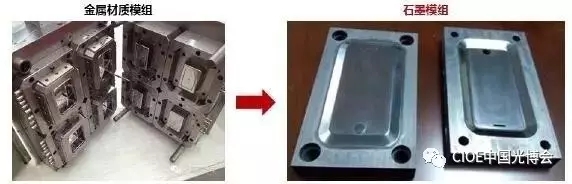

Graphite molds affect 3D glass surface finish and radian. Compared with metal materials at high temperature deformation, easy to soft, graphite with high temperature, high hardness, good conductivity, radiation, corrosion resistance, low cost characteristics. So the glass bending die using graphite material to produce, can guarantee the greatest degree of precision. Graphite mold as an important supplies, the life of a direct impact on the cost of bending machine.

The bending machine uses graphite mold instead of metal mold

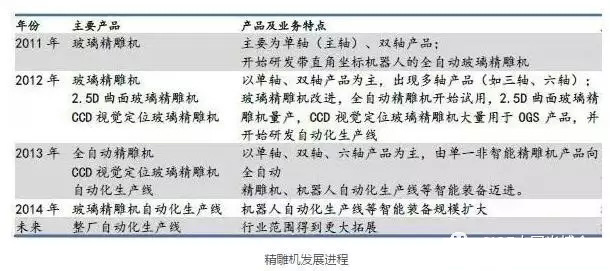

Engraving machine: intelligent and flexible

From the traditional glass carving machine to the CCD visual positioning glass carving machine, multi-spindle carving machine and then fully automated carved machine, glass carved machine has also experienced a continuous evolution of the upgrade process.

Engraving machine development process

The traditional glass carving machine for the mobile phone, tablet computer and other touch products, glass panels for drilling, slotting and finishing outside processing. The higher the number of shafts, the higher the machining efficiency, including uniaxial, biaxial and six-axis products.

The traditional glass carving machine includes uniaxial, biaxial and six-axis products

CCD vision positioning glass engraving machine will be visual technology and processing technology, with high precision, fast, high efficiency, no sand, no collapse and other characteristics, suitable for high-quality one-glass (OGS) products, glass panel processing The

Automatic glass engraving machine to install automatic loading and unloading device (manipulator, that is, rectangular coordinate robot), can save a lot of manpower and material resources, one person can be executive 10 sets of Taiwan; center positioning additional fixture to ensure accurate positioning of glass; Life alarm tips to prevent the tool wear caused by poor processing of glass products; processing inspection alarm tips, you can set any time prompted to test processing products.

Surface polishing machine: the trend of domestic substitution is strong

3D glass complex shape, processing technology requires a higher, and imports of 3D glass polishing machine equipment is expensive, long lead times, equipment maintenance is not convenient. After several years of development, the domestic for 3D cover glass processing surface polishing machine has become more mature, yield can reach more than 90%.

三、 3D glass processing equipment market space analysis

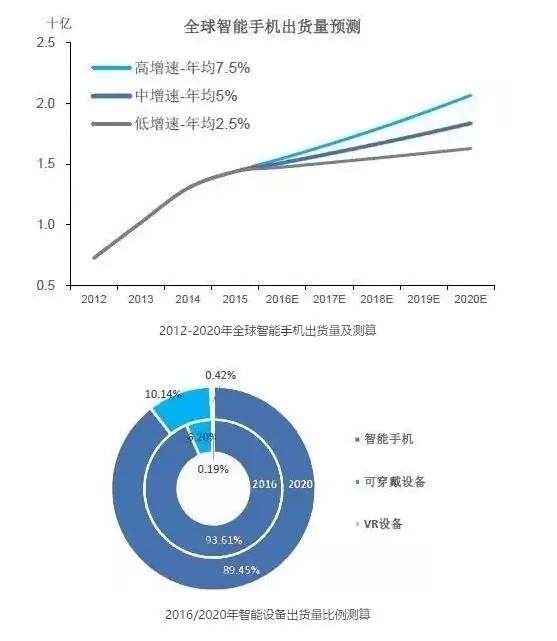

Intelligent terminal demand determines the market space for 3D surface glass, where smartphones are the largest application area.

Smart phone two camps, Andrews Samsung, Huawei, Vivo, OPPO, millet and so have launched 3D glass cover phone models. The market is expected to Apple iPhone8 will be equipped with 3D glass cover and back cover.

Currently used / planned to use 3D glass cover for smartphone models

According to the relevant agencies predicted that in 2020 the annual demand for 3D glass cover 6-14 billion, the penetration rate of 23% -54%.

2016 - Changes in demand and permeability of 3D glass panels in 2020

At the same time, the domestic glass cover manufacturers are also increasing the amount of 3D glass production capacity investment, 2017 industry capacity is expected to 130 million or so.

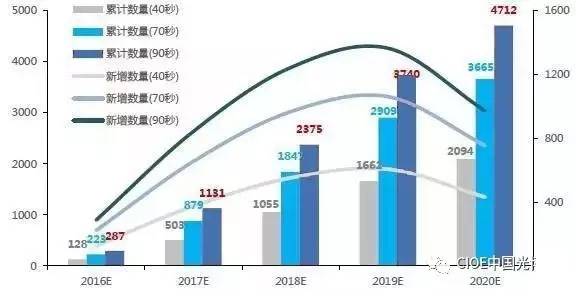

Hot bending machine market forecast

2016 - Added number and cumulative quantity forecast for hot bending machine in 2020 (with: the left axis is the cumulative quantity and the right axis is the new quantity)

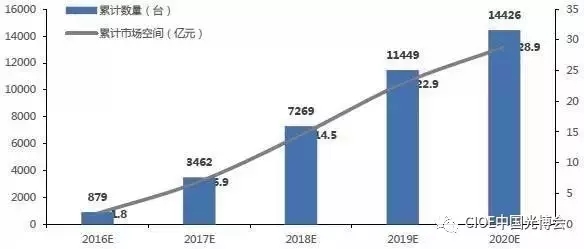

Carved machine market forecast

Industry research data show that 2D processing time 2-3 minutes, 2.5D processing time 5 minutes, 3D processing time 3 minutes; carved machine is generally double, once out of 2, yield can reach 95-98%. At present carved machine industry to maintain about 10 million units, the future demand is mainly automated equipment upgrades. It is estimated that by 2020, for the Amotech 3D glass processing carving machine cumulative demand is about 15,000 units, corresponding to the market space of about 2.9 billion.

2016 - Total number of engraving machines (table) and market space for 3D glass processing in 2020 (100 million yuan)

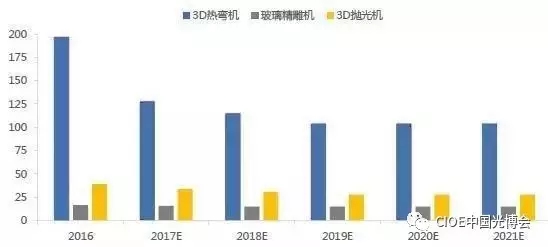

2016 - 2021 3D bending machine, glass carving machine, 3D polishing machine price trends (million)