(function(A,w){function ma(){if(!c.isReady){try{s.documentElement.doScroll("left")}catch(a){setTimeout(ma,1);return}c.ready()}}function Qa(a,b){b.src?c.ajax({url:b.src,async:false,dataType:"script"}):c.globalEval(b.text||b.textContent||b.innerHTML||"");b.parentNode&&b.parentNode.removeChild(b)}function X(a,b,d,f,e,j){var i=a.length;if(typeof b==="object"){for(var o in b)X(a,o,b[o],f,e,d);return a}if(d!==w){f=!j&&f&&c.isFunction(d);for(o=0;o

)[^>]*$|^#([\w-]+)$/,Ua=/^.[^:#\[\.,]*$/,Va=/\S/,

Wa=/^(\s|\u00A0)+|(\s|\u00A0)+$/g,Xa=/^<(\w+)\s*\/?>(?:<\/\1>)?$/,P=navigator.userAgent,xa=false,Q=[],L,$=Object.prototype.toString,aa=Object.prototype.hasOwnProperty,ba=Array.prototype.push,R=Array.prototype.slice,ya=Array.prototype.indexOf;c.fn=c.prototype={init:function(a,b){var d,f;if(!a)return this;if(a.nodeType){this.context=this[0]=a;this.length=1;return this}if(a==="body"&&!b){this.context=s;this[0]=s.body;this.selector="body";this.length=1;return this}if(typeof a==="string")if((d=Ta.exec(a))&&

(d[1]||!b))if(d[1]){f=b?b.ownerDocument||b:s;if(a=Xa.exec(a))if(c.isPlainObject(b)){a=[s.createElement(a[1])];c.fn.attr.call(a,b,true)}else a=[f.createElement(a[1])];else{a=sa([d[1]],[f]);a=(a.cacheable?a.fragment.cloneNode(true):a.fragment).childNodes}return c.merge(this,a)}else{if(b=s.getElementById(d[2])){if(b.id!==d[2])return T.find(a);this.length=1;this[0]=b}this.context=s;this.selector=a;return this}else if(!b&&/^\w+$/.test(a)){this.selector=a;this.context=s;a=s.getElementsByTagName(a);return c.merge(this,

a)}else return!b||b.jquery?(b||T).find(a):c(b).find(a);else if(c.isFunction(a))return T.ready(a);if(a.selector!==w){this.selector=a.selector;this.context=a.context}return c.makeArray(a,this)},selector:"",jquery:"1.4.2",length:0,size:function(){return this.length},toArray:function(){return R.call(this,0)},get:function(a){return a==null?this.toArray():a<0?this.slice(a)[0]:this[a]},pushStack:function(a,b,d){var f=c();c.isArray(a)?ba.apply(f,a):c.merge(f,a);f.prevObject=this;f.context=this.context;if(b=== "find")f.selector=this.selector+(this.selector?" ":"")+d;else if(b)f.selector=this.selector+"."+b+"("+d+")";return f},each:function(a,b){return c.each(this,a,b)},ready:function(a){c.bindReady();if(c.isReady)a.call(s,c);else Q&&Q.push(a);return this},eq:function(a){return a===-1?this.slice(a):this.slice(a,+a+1)},first:function(){return this.eq(0)},last:function(){return this.eq(-1)},slice:function(){return this.pushStack(R.apply(this,arguments),"slice",R.call(arguments).join(","))},map:function(a){return this.pushStack(c.map(this, function(b,d){return a.call(b,d,b)}))},end:function(){return this.prevObject||c(null)},push:ba,sort:[].sort,splice:[].splice};c.fn.init.prototype=c.fn;c.extend=c.fn.extend=function(){var a=arguments[0]||{},b=1,d=arguments.length,f=false,e,j,i,o;if(typeof a==="boolean"){f=a;a=arguments[1]||{};b=2}if(typeof a!=="object"&&!c.isFunction(a))a={};if(d===b){a=this;--b}for(;b

a";

var e=d.getElementsByTagName("*"),j=d.getElementsByTagName("a")[0];if(!(!e||!e.length||!j)){c.support={leadingWhitespace:d.firstChild.nodeType===3,tbody:!d.getElementsByTagName("tbody").length,htmlSerialize:!!d.getElementsByTagName("link").length,style:/red/.test(j.getAttribute("style")),hrefNormalized:j.getAttribute("href")==="/a",opacity:/^0.55$/.test(j.style.opacity),cssFloat:!!j.style.cssFloat,checkOn:d.getElementsByTagName("input")[0].value==="on",optSelected:s.createElement("select").appendChild(s.createElement("option")).selected,

parentNode:d.removeChild(d.appendChild(s.createElement("div"))).parentNode===null,deleteExpando:true,checkClone:false,scriptEval:false,noCloneEvent:true,boxModel:null};b.type="text/javascript";try{b.appendChild(s.createTextNode("window."+f+"=1;"))}catch(i){}a.insertBefore(b,a.firstChild);if(A[f]){c.support.scriptEval=true;delete A[f]}try{delete b.test}catch(o){c.support.deleteExpando=false}a.removeChild(b);if(d.attachEvent&&d.fireEvent){d.attachEvent("onclick",function k(){c.support.noCloneEvent=

false;d.detachEvent("onclick",k)});d.cloneNode(true).fireEvent("onclick")}d=s.createElement("div");d.innerHTML="";a=s.createDocumentFragment();a.appendChild(d.firstChild);c.support.checkClone=a.cloneNode(true).cloneNode(true).lastChild.checked;c(function(){var k=s.createElement("div");k.style.width=k.style.paddingLeft="1px";s.body.appendChild(k);c.boxModel=c.support.boxModel=k.offsetWidth===2;s.body.removeChild(k).style.display="none"});a=function(k){var n=

s.createElement("div");k="on"+k;var r=k in n;if(!r){n.setAttribute(k,"return;");r=typeof n[k]==="function"}return r};c.support.submitBubbles=a("submit");c.support.changeBubbles=a("change");a=b=d=e=j=null}})();c.props={"for":"htmlFor","class":"className",readonly:"readOnly",maxlength:"maxLength",cellspacing:"cellSpacing",rowspan:"rowSpan",colspan:"colSpan",tabindex:"tabIndex",usemap:"useMap",frameborder:"frameBorder"};var G="jQuery"+J(),Ya=0,za={};c.extend({cache:{},expando:G,noData:{embed:true,object:true,

applet:true},data:function(a,b,d){if(!(a.nodeName&&c.noData[a.nodeName.toLowerCase()])){a=a==A?za:a;var f=a[G],e=c.cache;if(!f&&typeof b==="string"&&d===w)return null;f||(f=++Ya);if(typeof b==="object"){a[G]=f;e[f]=c.extend(true,{},b)}else if(!e[f]){a[G]=f;e[f]={}}a=e[f];if(d!==w)a[b]=d;return typeof b==="string"?a[b]:a}},removeData:function(a,b){if(!(a.nodeName&&c.noData[a.nodeName.toLowerCase()])){a=a==A?za:a;var d=a[G],f=c.cache,e=f[d];if(b){if(e){delete e[b];c.isEmptyObject(e)&&c.removeData(a)}}else{if(c.support.deleteExpando)delete a[c.expando];

else a.removeAttribute&&a.removeAttribute(c.expando);delete f[d]}}}});c.fn.extend({data:function(a,b){if(typeof a==="undefined"&&this.length)return c.data(this[0]);else if(typeof a==="object")return this.each(function(){c.data(this,a)});var d=a.split(".");d[1]=d[1]?"."+d[1]:"";if(b===w){var f=this.triggerHandler("getData"+d[1]+"!",[d[0]]);if(f===w&&this.length)f=c.data(this[0],a);return f===w&&d[1]?this.data(d[0]):f}else return this.trigger("setData"+d[1]+"!",[d[0],b]).each(function(){c.data(this,

a,b)})},removeData:function(a){return this.each(function(){c.removeData(this,a)})}});c.extend({queue:function(a,b,d){if(a){b=(b||"fx")+"queue";var f=c.data(a,b);if(!d)return f||[];if(!f||c.isArray(d))f=c.data(a,b,c.makeArray(d));else f.push(d);return f}},dequeue:function(a,b){b=b||"fx";var d=c.queue(a,b),f=d.shift();if(f==="inprogress")f=d.shift();if(f){b==="fx"&&d.unshift("inprogress");f.call(a,function(){c.dequeue(a,b)})}}});c.fn.extend({queue:function(a,b){if(typeof a!=="string"){b=a;a="fx"}if(b===

w)return c.queue(this[0],a);return this.each(function(){var d=c.queue(this,a,b);a==="fx"&&d[0]!=="inprogress"&&c.dequeue(this,a)})},dequeue:function(a){return this.each(function(){c.dequeue(this,a)})},delay:function(a,b){a=c.fx?c.fx.speeds[a]||a:a;b=b||"fx";return this.queue(b,function(){var d=this;setTimeout(function(){c.dequeue(d,b)},a)})},clearQueue:function(a){return this.queue(a||"fx",[])}});var Aa=/[\n\t]/g,ca=/\s+/,Za=/\r/g,$a=/href|src|style/,ab=/(button|input)/i,bb=/(button|input|object|select|textarea)/i,

cb=/^(a|area)$/i,Ba=/radio|checkbox/;c.fn.extend({attr:function(a,b){return X(this,a,b,true,c.attr)},removeAttr:function(a){return this.each(function(){c.attr(this,a,"");this.nodeType===1&&this.removeAttribute(a)})},addClass:function(a){if(c.isFunction(a))return this.each(function(n){var r=c(this);r.addClass(a.call(this,n,r.attr("class")))});if(a&&typeof a==="string")for(var b=(a||"").split(ca),d=0,f=this.length;d-1)return true;return false},val:function(a){if(a===w){var b=this[0];if(b){if(c.nodeName(b,"option"))return(b.attributes.value||{}).specified?b.value:b.text;if(c.nodeName(b,"select")){var d=b.selectedIndex,f=[],e=b.options;b=b.type==="select-one";if(d<0)return null;var j=b?d:0;for(d=b?d+1:e.length;j=0;else if(c.nodeName(this,"select")){var u=c.makeArray(r);c("option",this).each(function(){this.selected=

c.inArray(c(this).val(),u)>=0});if(!u.length)this.selectedIndex=-1}else this.value=r}})}});c.extend({attrFn:{val:true,css:true,html:true,text:true,data:true,width:true,height:true,offset:true},attr:function(a,b,d,f){if(!a||a.nodeType===3||a.nodeType===8)return w;if(f&&b in c.attrFn)return c(a)[b](d);f=a.nodeType!==1||!c.isXMLDoc(a);var e=d!==w;b=f&&c.props[b]||b;if(a.nodeType===1){var j=$a.test(b);if(b in a&&f&&!j){if(e){b==="type"&&ab.test(a.nodeName)&&a.parentNode&&c.error("type property can't be changed");

a[b]=d}if(c.nodeName(a,"form")&&a.getAttributeNode(b))return a.getAttributeNode(b).nodeValue;if(b==="tabIndex")return(b=a.getAttributeNode("tabIndex"))&&b.specified?b.value:bb.test(a.nodeName)||cb.test(a.nodeName)&&a.href?0:w;return a[b]}if(!c.support.style&&f&&b==="style"){if(e)a.style.cssText=""+d;return a.style.cssText}e&&a.setAttribute(b,""+d);a=!c.support.hrefNormalized&&f&&j?a.getAttribute(b,2):a.getAttribute(b);return a===null?w:a}return c.style(a,b,d)}});var O=/\.(.*)$/,db=function(a){return a.replace(/[^\w\s\.\|`]/g,

function(b){return"\\"+b})};c.event={add:function(a,b,d,f){if(!(a.nodeType===3||a.nodeType===8)){if(a.setInterval&&a!==A&&!a.frameElement)a=A;var e,j;if(d.handler){e=d;d=e.handler}if(!d.guid)d.guid=c.guid++;if(j=c.data(a)){var i=j.events=j.events||{},o=j.handle;if(!o)j.handle=o=function(){return typeof c!=="undefined"&&!c.event.triggered?c.event.handle.apply(o.elem,arguments):w};o.elem=a;b=b.split(" ");for(var k,n=0,r;k=b[n++];){j=e?c.extend({},e):{handler:d,data:f};if(k.indexOf(".")>-1){r=k.split(".");

k=r.shift();j.namespace=r.slice(0).sort().join(".")}else{r=[];j.namespace=""}j.type=k;j.guid=d.guid;var u=i[k],z=c.event.special[k]||{};if(!u){u=i[k]=[];if(!z.setup||z.setup.call(a,f,r,o)===false)if(a.addEventListener)a.addEventListener(k,o,false);else a.attachEvent&&a.attachEvent("on"+k,o)}if(z.add){z.add.call(a,j);if(!j.handler.guid)j.handler.guid=d.guid}u.push(j);c.event.global[k]=true}a=null}}},global:{},remove:function(a,b,d,f){if(!(a.nodeType===3||a.nodeType===8)){var e,j=0,i,o,k,n,r,u,z=c.data(a),

C=z&&z.events;if(z&&C){if(b&&b.type){d=b.handler;b=b.type}if(!b||typeof b==="string"&&b.charAt(0)==="."){b=b||"";for(e in C)c.event.remove(a,e+b)}else{for(b=b.split(" ");e=b[j++];){n=e;i=e.indexOf(".")<0;o=[];if(!i){o=e.split(".");e=o.shift();k=new RegExp("(^|\\.)"+c.map(o.slice(0).sort(),db).join("\\.(?:.*\\.)?")+"(\\.|$)")}if(r=C[e])if(d){n=c.event.special[e]||{};for(B=f||0;B=0){a.type=

e=e.slice(0,-1);a.exclusive=true}if(!d){a.stopPropagation();c.event.global[e]&&c.each(c.cache,function(){this.events&&this.events[e]&&c.event.trigger(a,b,this.handle.elem)})}if(!d||d.nodeType===3||d.nodeType===8)return w;a.result=w;a.target=d;b=c.makeArray(b);b.unshift(a)}a.currentTarget=d;(f=c.data(d,"handle"))&&f.apply(d,b);f=d.parentNode||d.ownerDocument;try{if(!(d&&d.nodeName&&c.noData[d.nodeName.toLowerCase()]))if(d["on"+e]&&d["on"+e].apply(d,b)===false)a.result=false}catch(j){}if(!a.isPropagationStopped()&&

f)c.event.trigger(a,b,f,true);else if(!a.isDefaultPrevented()){f=a.target;var i,o=c.nodeName(f,"a")&&e==="click",k=c.event.special[e]||{};if((!k._default||k._default.call(d,a)===false)&&!o&&!(f&&f.nodeName&&c.noData[f.nodeName.toLowerCase()])){try{if(f[e]){if(i=f["on"+e])f["on"+e]=null;c.event.triggered=true;f[e]()}}catch(n){}if(i)f["on"+e]=i;c.event.triggered=false}}},handle:function(a){var b,d,f,e;a=arguments[0]=c.event.fix(a||A.event);a.currentTarget=this;b=a.type.indexOf(".")<0&&!a.exclusive; if(!b){d=a.type.split(".");a.type=d.shift();f=new RegExp("(^|\\.)"+d.slice(0).sort().join("\\.(?:.*\\.)?")+"(\\.|$)")}e=c.data(this,"events");d=e[a.type];if(e&&d){d=d.slice(0);e=0;for(var j=d.length;e-1?c.map(a.options,function(f){return f.selected}).join("-"):"";else if(a.nodeName.toLowerCase()==="select")d=a.selectedIndex;return d},fa=function(a,b){var d=a.target,f,e;if(!(!da.test(d.nodeName)||d.readOnly)){f=c.data(d,"_change_data");e=Fa(d);if(a.type!=="focusout"||d.type!=="radio")c.data(d,"_change_data",

e);if(!(f===w||e===f))if(f!=null||e){a.type="change";return c.event.trigger(a,b,d)}}};c.event.special.change={filters:{focusout:fa,click:function(a){var b=a.target,d=b.type;if(d==="radio"||d==="checkbox"||b.nodeName.toLowerCase()==="select")return fa.call(this,a)},keydown:function(a){var b=a.target,d=b.type;if(a.keyCode===13&&b.nodeName.toLowerCase()!=="textarea"||a.keyCode===32&&(d==="checkbox"||d==="radio")||d==="select-multiple")return fa.call(this,a)},beforeactivate:function(a){a=a.target;c.data(a,

"_change_data",Fa(a))}},setup:function(){if(this.type==="file")return false;for(var a in ea)c.event.add(this,a+".specialChange",ea[a]);return da.test(this.nodeName)},teardown:function(){c.event.remove(this,".specialChange");return da.test(this.nodeName)}};ea=c.event.special.change.filters}s.addEventListener&&c.each({focus:"focusin",blur:"focusout"},function(a,b){function d(f){f=c.event.fix(f);f.type=b;return c.event.handle.call(this,f)}c.event.special[b]={setup:function(){this.addEventListener(a,

d,true)},teardown:function(){this.removeEventListener(a,d,true)}}});c.each(["bind","one"],function(a,b){c.fn[b]=function(d,f,e){if(typeof d==="object"){for(var j in d)this[b](j,f,d[j],e);return this}if(c.isFunction(f)){e=f;f=w}var i=b==="one"?c.proxy(e,function(k){c(this).unbind(k,i);return e.apply(this,arguments)}):e;if(d==="unload"&&b!=="one")this.one(d,f,e);else{j=0;for(var o=this.length;j0){y=t;break}}t=t[g]}m[q]=y}}}var f=/((?:\((?:\([^()]+\)|[^()]+)+\)|\[(?:\[[^[\]]*\]|['"][^'"]*['"]|[^[\]'"]+)+\]|\\.|[^ >+~,(\[\\]+)+|[>+~])(\s*,\s*)?((?:.|\r|\n)*)/g,

e=0,j=Object.prototype.toString,i=false,o=true;[0,0].sort(function(){o=false;return 0});var k=function(g,h,l,m){l=l||[];var q=h=h||s;if(h.nodeType!==1&&h.nodeType!==9)return[];if(!g||typeof g!=="string")return l;for(var p=[],v,t,y,S,H=true,M=x(h),I=g;(f.exec(""),v=f.exec(I))!==null;){I=v[3];p.push(v[1]);if(v[2]){S=v[3];break}}if(p.length>1&&r.exec(g))if(p.length===2&&n.relative[p[0]])t=ga(p[0]+p[1],h);else for(t=n.relative[p[0]]?[h]:k(p.shift(),h);p.length;){g=p.shift();if(n.relative[g])g+=p.shift();

t=ga(g,t)}else{if(!m&&p.length>1&&h.nodeType===9&&!M&&n.match.ID.test(p[0])&&!n.match.ID.test(p[p.length-1])){v=k.find(p.shift(),h,M);h=v.expr?k.filter(v.expr,v.set)[0]:v.set[0]}if(h){v=m?{expr:p.pop(),set:z(m)}:k.find(p.pop(),p.length===1&&(p[0]==="~"||p[0]==="+")&&h.parentNode?h.parentNode:h,M);t=v.expr?k.filter(v.expr,v.set):v.set;if(p.length>0)y=z(t);else H=false;for(;p.length;){var D=p.pop();v=D;if(n.relative[D])v=p.pop();else D="";if(v==null)v=h;n.relative[D](y,v,M)}}else y=[]}y||(y=t);y||k.error(D||

g);if(j.call(y)==="[object Array]")if(H)if(h&&h.nodeType===1)for(g=0;y[g]!=null;g++){if(y[g]&&(y[g]===true||y[g].nodeType===1&&E(h,y[g])))l.push(t[g])}else for(g=0;y[g]!=null;g++)y[g]&&y[g].nodeType===1&&l.push(t[g]);else l.push.apply(l,y);else z(y,l);if(S){k(S,q,l,m);k.uniqueSort(l)}return l};k.uniqueSort=function(g){if(B){i=o;g.sort(B);if(i)for(var h=1;h":function(g,h){var l=typeof h==="string";if(l&&!/\W/.test(h)){h=h.toLowerCase();for(var m=0,q=g.length;m=0))l||m.push(v);else if(l)h[p]=false;return false},ID:function(g){return g[1].replace(/\\/g,"")},TAG:function(g){return g[1].toLowerCase()},

CHILD:function(g){if(g[1]==="nth"){var h=/(-?)(\d*)n((?:\+|-)?\d*)/.exec(g[2]==="even"&&"2n"||g[2]==="odd"&&"2n+1"||!/\D/.test(g[2])&&"0n+"+g[2]||g[2]);g[2]=h[1]+(h[2]||1)-0;g[3]=h[3]-0}g[0]=e++;return g},ATTR:function(g,h,l,m,q,p){h=g[1].replace(/\\/g,"");if(!p&&n.attrMap[h])g[1]=n.attrMap[h];if(g[2]==="~=")g[4]=" "+g[4]+" ";return g},PSEUDO:function(g,h,l,m,q){if(g[1]==="not")if((f.exec(g[3])||"").length>1||/^\w/.test(g[3]))g[3]=k(g[3],null,null,h);else{g=k.filter(g[3],h,l,true^q);l||m.push.apply(m,

g);return false}else if(n.match.POS.test(g[0])||n.match.CHILD.test(g[0]))return true;return g},POS:function(g){g.unshift(true);return g}},filters:{enabled:function(g){return g.disabled===false&&g.type!=="hidden"},disabled:function(g){return g.disabled===true},checked:function(g){return g.checked===true},selected:function(g){return g.selected===true},parent:function(g){return!!g.firstChild},empty:function(g){return!g.firstChild},has:function(g,h,l){return!!k(l[3],g).length},header:function(g){return/h\d/i.test(g.nodeName)},

text:function(g){return"text"===g.type},radio:function(g){return"radio"===g.type},checkbox:function(g){return"checkbox"===g.type},file:function(g){return"file"===g.type},password:function(g){return"password"===g.type},submit:function(g){return"submit"===g.type},image:function(g){return"image"===g.type},reset:function(g){return"reset"===g.type},button:function(g){return"button"===g.type||g.nodeName.toLowerCase()==="button"},input:function(g){return/input|select|textarea|button/i.test(g.nodeName)}},

setFilters:{first:function(g,h){return h===0},last:function(g,h,l,m){return h===m.length-1},even:function(g,h){return h%2===0},odd:function(g,h){return h%2===1},lt:function(g,h,l){return hl[3]-0},nth:function(g,h,l){return l[3]-0===h},eq:function(g,h,l){return l[3]-0===h}},filter:{PSEUDO:function(g,h,l,m){var q=h[1],p=n.filters[q];if(p)return p(g,l,h,m);else if(q==="contains")return(g.textContent||g.innerText||a([g])||"").indexOf(h[3])>=0;else if(q==="not"){h=

h[3];l=0;for(m=h.length;l=0}},ID:function(g,h){return g.nodeType===1&&g.getAttribute("id")===h},TAG:function(g,h){return h==="*"&&g.nodeType===1||g.nodeName.toLowerCase()===h},CLASS:function(g,h){return(" "+(g.className||g.getAttribute("class"))+" ").indexOf(h)>-1},ATTR:function(g,h){var l=h[1];g=n.attrHandle[l]?n.attrHandle[l](g):g[l]!=null?g[l]:g.getAttribute(l);l=g+"";var m=h[2];h=h[4];return g==null?m==="!=":m===

"="?l===h:m==="*="?l.indexOf(h)>=0:m==="~="?(" "+l+" ").indexOf(h)>=0:!h?l&&g!==false:m==="!="?l!==h:m==="^="?l.indexOf(h)===0:m==="$="?l.substr(l.length-h.length)===h:m==="|="?l===h||l.substr(0,h.length+1)===h+"-":false},POS:function(g,h,l,m){var q=n.setFilters[h[2]];if(q)return q(g,l,h,m)}}},r=n.match.POS;for(var u in n.match){n.match[u]=new RegExp(n.match[u].source+/(?![^\[]*\])(?![^\(]*\))/.source);n.leftMatch[u]=new RegExp(/(^(?:.|\r|\n)*?)/.source+n.match[u].source.replace(/\\(\d+)/g,function(g,

h){return"\\"+(h-0+1)}))}var z=function(g,h){g=Array.prototype.slice.call(g,0);if(h){h.push.apply(h,g);return h}return g};try{Array.prototype.slice.call(s.documentElement.childNodes,0)}catch(C){z=function(g,h){h=h||[];if(j.call(g)==="[object Array]")Array.prototype.push.apply(h,g);else if(typeof g.length==="number")for(var l=0,m=g.length;l";var l=s.documentElement;l.insertBefore(g,l.firstChild);if(s.getElementById(h)){n.find.ID=function(m,q,p){if(typeof q.getElementById!=="undefined"&&!p)return(q=q.getElementById(m[1]))?q.id===m[1]||typeof q.getAttributeNode!=="undefined"&&

q.getAttributeNode("id").nodeValue===m[1]?[q]:w:[]};n.filter.ID=function(m,q){var p=typeof m.getAttributeNode!=="undefined"&&m.getAttributeNode("id");return m.nodeType===1&&p&&p.nodeValue===q}}l.removeChild(g);l=g=null})();(function(){var g=s.createElement("div");g.appendChild(s.createComment(""));if(g.getElementsByTagName("*").length>0)n.find.TAG=function(h,l){l=l.getElementsByTagName(h[1]);if(h[1]==="*"){h=[];for(var m=0;l[m];m++)l[m].nodeType===1&&h.push(l[m]);l=h}return l};g.innerHTML="";

if(g.firstChild&&typeof g.firstChild.getAttribute!=="undefined"&&g.firstChild.getAttribute("href")!=="#")n.attrHandle.href=function(h){return h.getAttribute("href",2)};g=null})();s.querySelectorAll&&function(){var g=k,h=s.createElement("div");h.innerHTML="

";if(!(h.querySelectorAll&&h.querySelectorAll(".TEST").length===0)){k=function(m,q,p,v){q=q||s;if(!v&&q.nodeType===9&&!x(q))try{return z(q.querySelectorAll(m),p)}catch(t){}return g(m,q,p,v)};for(var l in g)k[l]=g[l];h=null}}();

(function(){var g=s.createElement("div");g.innerHTML="

";if(!(!g.getElementsByClassName||g.getElementsByClassName("e").length===0)){g.lastChild.className="e";if(g.getElementsByClassName("e").length!==1){n.order.splice(1,0,"CLASS");n.find.CLASS=function(h,l,m){if(typeof l.getElementsByClassName!=="undefined"&&!m)return l.getElementsByClassName(h[1])};g=null}}})();var E=s.compareDocumentPosition?function(g,h){return!!(g.compareDocumentPosition(h)&16)}:

function(g,h){return g!==h&&(g.contains?g.contains(h):true)},x=function(g){return(g=(g?g.ownerDocument||g:0).documentElement)?g.nodeName!=="HTML":false},ga=function(g,h){var l=[],m="",q;for(h=h.nodeType?[h]:h;q=n.match.PSEUDO.exec(g);){m+=q[0];g=g.replace(n.match.PSEUDO,"")}g=n.relative[g]?g+"*":g;q=0;for(var p=h.length;q=0===d})};c.fn.extend({find:function(a){for(var b=this.pushStack("","find",a),d=0,f=0,e=this.length;f0)for(var j=d;j0},closest:function(a,b){if(c.isArray(a)){var d=[],f=this[0],e,j=

{},i;if(f&&a.length){e=0;for(var o=a.length;e-1:c(f).is(e)){d.push({selector:i,elem:f});delete j[i]}}f=f.parentNode}}return d}var k=c.expr.match.POS.test(a)?c(a,b||this.context):null;return this.map(function(n,r){for(;r&&r.ownerDocument&&r!==b;){if(k?k.index(r)>-1:c(r).is(a))return r;r=r.parentNode}return null})},index:function(a){if(!a||typeof a===

"string")return c.inArray(this[0],a?c(a):this.parent().children());return c.inArray(a.jquery?a[0]:a,this)},add:function(a,b){a=typeof a==="string"?c(a,b||this.context):c.makeArray(a);b=c.merge(this.get(),a);return this.pushStack(qa(a[0])||qa(b[0])?b:c.unique(b))},andSelf:function(){return this.add(this.prevObject)}});c.each({parent:function(a){return(a=a.parentNode)&&a.nodeType!==11?a:null},parents:function(a){return c.dir(a,"parentNode")},parentsUntil:function(a,b,d){return c.dir(a,"parentNode",

d)},next:function(a){return c.nth(a,2,"nextSibling")},prev:function(a){return c.nth(a,2,"previousSibling")},nextAll:function(a){return c.dir(a,"nextSibling")},prevAll:function(a){return c.dir(a,"previousSibling")},nextUntil:function(a,b,d){return c.dir(a,"nextSibling",d)},prevUntil:function(a,b,d){return c.dir(a,"previousSibling",d)},siblings:function(a){return c.sibling(a.parentNode.firstChild,a)},children:function(a){return c.sibling(a.firstChild)},contents:function(a){return c.nodeName(a,"iframe")?

a.contentDocument||a.contentWindow.document:c.makeArray(a.childNodes)}},function(a,b){c.fn[a]=function(d,f){var e=c.map(this,b,d);eb.test(a)||(f=d);if(f&&typeof f==="string")e=c.filter(f,e);e=this.length>1?c.unique(e):e;if((this.length>1||gb.test(f))&&fb.test(a))e=e.reverse();return this.pushStack(e,a,R.call(arguments).join(","))}});c.extend({filter:function(a,b,d){if(d)a=":not("+a+")";return c.find.matches(a,b)},dir:function(a,b,d){var f=[];for(a=a[b];a&&a.nodeType!==9&&(d===w||a.nodeType!==1||!c(a).is(d));){a.nodeType===

1&&f.push(a);a=a[b]}return f},nth:function(a,b,d){b=b||1;for(var f=0;a;a=a[d])if(a.nodeType===1&&++f===b)break;return a},sibling:function(a,b){for(var d=[];a;a=a.nextSibling)a.nodeType===1&&a!==b&&d.push(a);return d}});var Ja=/ jQuery\d+="(?:\d+|null)"/g,V=/^\s+/,Ka=/(<([\w:]+)[^>]*?)\/>/g,hb=/^(?:area|br|col|embed|hr|img|input|link|meta|param)$/i,La=/<([\w:]+)/,ib=/"},F={option:[1,""],legend:[1,"

"],thead:[1,"

"],tr:[2,"

"],td:[3,"

"],col:[2,"

"],area:[1,"

"],_default:[0,"",""]};F.optgroup=F.option;F.tbody=F.tfoot=F.colgroup=F.caption=F.thead;F.th=F.td;if(!c.support.htmlSerialize)F._default=[1,"div

","

"];c.fn.extend({text:function(a){if(c.isFunction(a))return this.each(function(b){var d=

c(this);d.text(a.call(this,b,d.text()))});if(typeof a!=="object"&&a!==w)return this.empty().append((this[0]&&this[0].ownerDocument||s).createTextNode(a));return c.text(this)},wrapAll:function(a){if(c.isFunction(a))return this.each(function(d){c(this).wrapAll(a.call(this,d))});if(this[0]){var b=c(a,this[0].ownerDocument).eq(0).clone(true);this[0].parentNode&&b.insertBefore(this[0]);b.map(function(){for(var d=this;d.firstChild&&d.firstChild.nodeType===1;)d=d.firstChild;return d}).append(this)}return this},

wrapInner:function(a){if(c.isFunction(a))return this.each(function(b){c(this).wrapInner(a.call(this,b))});return this.each(function(){var b=c(this),d=b.contents();d.length?d.wrapAll(a):b.append(a)})},wrap:function(a){return this.each(function(){c(this).wrapAll(a)})},unwrap:function(){return this.parent().each(function(){c.nodeName(this,"body")||c(this).replaceWith(this.childNodes)}).end()},append:function(){return this.domManip(arguments,true,function(a){this.nodeType===1&&this.appendChild(a)})},

prepend:function(){return this.domManip(arguments,true,function(a){this.nodeType===1&&this.insertBefore(a,this.firstChild)})},before:function(){if(this[0]&&this[0].parentNode)return this.domManip(arguments,false,function(b){this.parentNode.insertBefore(b,this)});else if(arguments.length){var a=c(arguments[0]);a.push.apply(a,this.toArray());return this.pushStack(a,"before",arguments)}},after:function(){if(this[0]&&this[0].parentNode)return this.domManip(arguments,false,function(b){this.parentNode.insertBefore(b,

this.nextSibling)});else if(arguments.length){var a=this.pushStack(this,"after",arguments);a.push.apply(a,c(arguments[0]).toArray());return a}},remove:function(a,b){for(var d=0,f;(f=this[d])!=null;d++)if(!a||c.filter(a,[f]).length){if(!b&&f.nodeType===1){c.cleanData(f.getElementsByTagName("*"));c.cleanData([f])}f.parentNode&&f.parentNode.removeChild(f)}return this},empty:function(){for(var a=0,b;(b=this[a])!=null;a++)for(b.nodeType===1&&c.cleanData(b.getElementsByTagName("*"));b.firstChild;)b.removeChild(b.firstChild);

return this},clone:function(a){var b=this.map(function(){if(!c.support.noCloneEvent&&!c.isXMLDoc(this)){var d=this.outerHTML,f=this.ownerDocument;if(!d){d=f.createElement("div");d.appendChild(this.cloneNode(true));d=d.innerHTML}return c.clean([d.replace(Ja,"").replace(/=([^="'>\s]+\/)>/g,'="$1">').replace(V,"")],f)[0]}else return this.cloneNode(true)});if(a===true){ra(this,b);ra(this.find("*"),b.find("*"))}return b},html:function(a){if(a===w)return this[0]&&this[0].nodeType===1?this[0].innerHTML.replace(Ja,

""):null;else if(typeof a==="string"&&!ta.test(a)&&(c.support.leadingWhitespace||!V.test(a))&&!F[(La.exec(a)||["",""])[1].toLowerCase()]){a=a.replace(Ka,Ma);try{for(var b=0,d=this.length;b0||e.cacheable||this.length>1?k.cloneNode(true):k)}o.length&&c.each(o,Qa)}return this}});c.fragments={};c.each({appendTo:"append",prependTo:"prepend",insertBefore:"before",insertAfter:"after",replaceAll:"replaceWith"},function(a,b){c.fn[a]=function(d){var f=[];d=c(d);var e=this.length===1&&this[0].parentNode;if(e&&e.nodeType===11&&e.childNodes.length===1&&d.length===1){d[b](this[0]);

return this}else{e=0;for(var j=d.length;e0?this.clone(true):this).get();c.fn[b].apply(c(d[e]),i);f=f.concat(i)}return this.pushStack(f,a,d.selector)}}});c.extend({clean:function(a,b,d,f){b=b||s;if(typeof b.createElement==="undefined")b=b.ownerDocument||b[0]&&b[0].ownerDocument||s;for(var e=[],j=0,i;(i=a[j])!=null;j++){if(typeof i==="number")i+="";if(i){if(typeof i==="string"&&!jb.test(i))i=b.createTextNode(i);else if(typeof i==="string"){i=i.replace(Ka,Ma);var o=(La.exec(i)||["",

""])[1].toLowerCase(),k=F[o]||F._default,n=k[0],r=b.createElement("div");for(r.innerHTML=k[1]+i+k[2];n--;)r=r.lastChild;if(!c.support.tbody){n=ib.test(i);o=o==="table"&&!n?r.firstChild&&r.firstChild.childNodes:k[1]==="

"&&!n?r.childNodes:[];for(k=o.length-1;k>=0;--k)c.nodeName(o[k],"tbody")&&!o[k].childNodes.length&&o[k].parentNode.removeChild(o[k])}!c.support.leadingWhitespace&&V.test(i)&&r.insertBefore(b.createTextNode(V.exec(i)[0]),r.firstChild);i=r.childNodes}if(i.nodeType)e.push(i);else e=

c.merge(e,i)}}if(d)for(j=0;e[j];j++)if(f&&c.nodeName(e[j],"script")&&(!e[j].type||e[j].type.toLowerCase()==="text/javascript"))f.push(e[j].parentNode?e[j].parentNode.removeChild(e[j]):e[j]);else{e[j].nodeType===1&&e.splice.apply(e,[j+1,0].concat(c.makeArray(e[j].getElementsByTagName("script"))));d.appendChild(e[j])}return e},cleanData:function(a){for(var b,d,f=c.cache,e=c.event.special,j=c.support.deleteExpando,i=0,o;(o=a[i])!=null;i++)if(d=o[c.expando]){b=f[d];if(b.events)for(var k in b.events)e[k]?

c.event.remove(o,k):Ca(o,k,b.handle);if(j)delete o[c.expando];else o.removeAttribute&&o.removeAttribute(c.expando);delete f[d]}}});var kb=/z-?index|font-?weight|opacity|zoom|line-?height/i,Na=/alpha\([^)]*\)/,Oa=/opacity=([^)]*)/,ha=/float/i,ia=/-([a-z])/ig,lb=/([A-Z])/g,mb=/^-?\d+(?:px)?$/i,nb=/^-?\d/,ob={position:"absolute",visibility:"hidden",display:"block"},pb=["Left","Right"],qb=["Top","Bottom"],rb=s.defaultView&&s.defaultView.getComputedStyle,Pa=c.support.cssFloat?"cssFloat":"styleFloat",ja=

function(a,b){return b.toUpperCase()};c.fn.css=function(a,b){return X(this,a,b,true,function(d,f,e){if(e===w)return c.curCSS(d,f);if(typeof e==="number"&&!kb.test(f))e+="px";c.style(d,f,e)})};c.extend({style:function(a,b,d){if(!a||a.nodeType===3||a.nodeType===8)return w;if((b==="width"||b==="height")&&parseFloat(d)<0)d=w;var f=a.style||a,e=d!==w;if(!c.support.opacity&&b==="opacity"){if(e){f.zoom=1;b=parseInt(d,10)+""==="NaN"?"":"alpha(opacity="+d*100+")";a=f.filter||c.curCSS(a,"filter")||"";f.filter= Na.test(a)?a.replace(Na,b):b}return f.filter&&f.filter.indexOf("opacity=")>=0?parseFloat(Oa.exec(f.filter)[1])/100+"":""}if(ha.test(b))b=Pa;b=b.replace(ia,ja);if(e)f[b]=d;return f[b]},css:function(a,b,d,f){if(b==="width"||b==="height"){var e,j=b==="width"?pb:qb;function i(){e=b==="width"?a.offsetWidth:a.offsetHeight;f!=="border"&&c.each(j,function(){f||(e-=parseFloat(c.curCSS(a,"padding"+this,true))||0);if(f==="margin")e+=parseFloat(c.curCSS(a,"margin"+this,true))||0;else e-=parseFloat(c.curCSS(a,

"border"+this+"Width",true))||0})}a.offsetWidth!==0?i():c.swap(a,ob,i);return Math.max(0,Math.round(e))}return c.curCSS(a,b,d)},curCSS:function(a,b,d){var f,e=a.style;if(!c.support.opacity&&b==="opacity"&&a.currentStyle){f=Oa.test(a.currentStyle.filter||"")?parseFloat(RegExp.$1)/100+"":"";return f===""?"1":f}if(ha.test(b))b=Pa;if(!d&&e&&e[b])f=e[b];else if(rb){if(ha.test(b))b="float";b=b.replace(lb,"-$1").toLowerCase();e=a.ownerDocument.defaultView;if(!e)return null;if(a=e.getComputedStyle(a,null))f=

a.getPropertyValue(b);if(b==="opacity"&&f==="")f="1"}else if(a.currentStyle){d=b.replace(ia,ja);f=a.currentStyle[b]||a.currentStyle[d];if(!mb.test(f)&&nb.test(f)){b=e.left;var j=a.runtimeStyle.left;a.runtimeStyle.left=a.currentStyle.left;e.left=d==="fontSize"?"1em":f||0;f=e.pixelLeft+"px";e.left=b;a.runtimeStyle.left=j}}return f},swap:function(a,b,d){var f={};for(var e in b){f[e]=a.style[e];a.style[e]=b[e]}d.call(a);for(e in b)a.style[e]=f[e]}});if(c.expr&&c.expr.filters){c.expr.filters.hidden=function(a){var b=

a.offsetWidth,d=a.offsetHeight,f=a.nodeName.toLowerCase()==="tr";return b===0&&d===0&&!f?true:b>0&&d>0&&!f?false:c.curCSS(a,"display")==="none"};c.expr.filters.visible=function(a){return!c.expr.filters.hidden(a)}}var sb=J(),tb=//gi,ub=/select|textarea/i,vb=/color|date|datetime|email|hidden|month|number|password|range|search|tel|text|time|url|week/i,N=/=\?(&|$)/,ka=/\?/,wb=/(\?|&)_=.*?(&|$)/,xb=/^(\w+:)?\/\/([^\/?#]+)/,yb=/%20/g,zb=c.fn.load;c.fn.extend({load:function(a,b,d){if(typeof a!==

"string")return zb.call(this,a);else if(!this.length)return this;var f=a.indexOf(" ");if(f>=0){var e=a.slice(f,a.length);a=a.slice(0,f)}f="GET";if(b)if(c.isFunction(b)){d=b;b=null}else if(typeof b==="object"){b=c.param(b,c.ajaxSettings.traditional);f="POST"}var j=this;c.ajax({url:a,type:f,dataType:"html",data:b,complete:function(i,o){if(o==="success"||o==="notmodified")j.html(e?c("

").append(i.responseText.replace(tb,"")).find(e):i.responseText);d&&j.each(d,[i.responseText,o,i])}});return this},

serialize:function(){return c.param(this.serializeArray())},serializeArray:function(){return this.map(function(){return this.elements?c.makeArray(this.elements):this}).filter(function(){return this.name&&!this.disabled&&(this.checked||ub.test(this.nodeName)||vb.test(this.type))}).map(function(a,b){a=c(this).val();return a==null?null:c.isArray(a)?c.map(a,function(d){return{name:b.name,value:d}}):{name:b.name,value:a}}).get()}});c.each("ajaxStart ajaxStop ajaxComplete ajaxError ajaxSuccess ajaxSend".split(" "),

function(a,b){c.fn[b]=function(d){return this.bind(b,d)}});c.extend({get:function(a,b,d,f){if(c.isFunction(b)){f=f||d;d=b;b=null}return c.ajax({type:"GET",url:a,data:b,success:d,dataType:f})},getScript:function(a,b){return c.get(a,null,b,"script")},getJSON:function(a,b,d){return c.get(a,b,d,"json")},post:function(a,b,d,f){if(c.isFunction(b)){f=f||d;d=b;b={}}return c.ajax({type:"POST",url:a,data:b,success:d,dataType:f})},ajaxSetup:function(a){c.extend(c.ajaxSettings,a)},ajaxSettings:{url:location.href,

global:true,type:"GET",contentType:"application/x-www-form-urlencoded",processData:true,async:true,xhr:A.XMLHttpRequest&&(A.location.protocol!=="file:"||!A.ActiveXObject)?function(){return new A.XMLHttpRequest}:function(){try{return new A.ActiveXObject("Microsoft.XMLHTTP")}catch(a){}},accepts:{xml:"application/xml, text/xml",html:"text/html",script:"text/javascript, application/javascript",json:"application/json, text/javascript",text:"text/plain",_default:"*/*"}},lastModified:{},etag:{},ajax:function(a){function b(){e.success&&

e.success.call(k,o,i,x);e.global&&f("ajaxSuccess",[x,e])}function d(){e.complete&&e.complete.call(k,x,i);e.global&&f("ajaxComplete",[x,e]);e.global&&!--c.active&&c.event.trigger("ajaxStop")}function f(q,p){(e.context?c(e.context):c.event).trigger(q,p)}var e=c.extend(true,{},c.ajaxSettings,a),j,i,o,k=a&&a.context||e,n=e.type.toUpperCase();if(e.data&&e.processData&&typeof e.data!=="string")e.data=c.param(e.data,e.traditional);if(e.dataType==="jsonp"){if(n==="GET")N.test(e.url)||(e.url+=(ka.test(e.url)?

"&":"?")+(e.jsonp||"callback")+"=?");else if(!e.data||!N.test(e.data))e.data=(e.data?e.data+"&":"")+(e.jsonp||"callback")+"=?";e.dataType="json"}if(e.dataType==="json"&&(e.data&&N.test(e.data)||N.test(e.url))){j=e.jsonpCallback||"jsonp"+sb++;if(e.data)e.data=(e.data+"").replace(N,"="+j+"$1");e.url=e.url.replace(N,"="+j+"$1");e.dataType="script";A[j]=A[j]||function(q){o=q;b();d();A[j]=w;try{delete A[j]}catch(p){}z&&z.removeChild(C)}}if(e.dataType==="script"&&e.cache===null)e.cache=false;if(e.cache===

false&&n==="GET"){var r=J(),u=e.url.replace(wb,"$1_="+r+"$2");e.url=u+(u===e.url?(ka.test(e.url)?"&":"?")+"_="+r:"")}if(e.data&&n==="GET")e.url+=(ka.test(e.url)?"&":"?")+e.data;e.global&&!c.active++&&c.event.trigger("ajaxStart");r=(r=xb.exec(e.url))&&(r[1]&&r[1]!==location.protocol||r[2]!==location.host);if(e.dataType==="script"&&n==="GET"&&r){var z=s.getElementsByTagName("head")[0]||s.documentElement,C=s.createElement("script");C.src=e.url;if(e.scriptCharset)C.charset=e.scriptCharset;if(!j){var B=

false;C.onload=C.onreadystatechange=function(){if(!B&&(!this.readyState||this.readyState==="loaded"||this.readyState==="complete")){B=true;b();d();C.onload=C.onreadystatechange=null;z&&C.parentNode&&z.removeChild(C)}}}z.insertBefore(C,z.firstChild);return w}var E=false,x=e.xhr();if(x){e.username?x.open(n,e.url,e.async,e.username,e.password):x.open(n,e.url,e.async);try{if(e.data||a&&a.contentType)x.setRequestHeader("Content-Type",e.contentType);if(e.ifModified){c.lastModified[e.url]&&x.setRequestHeader("If-Modified-Since",

c.lastModified[e.url]);c.etag[e.url]&&x.setRequestHeader("If-None-Match",c.etag[e.url])}r||x.setRequestHeader("X-Requested-With","XMLHttpRequest");x.setRequestHeader("Accept",e.dataType&&e.accepts[e.dataType]?e.accepts[e.dataType]+", */*":e.accepts._default)}catch(ga){}if(e.beforeSend&&e.beforeSend.call(k,x,e)===false){e.global&&!--c.active&&c.event.trigger("ajaxStop");x.abort();return false}e.global&&f("ajaxSend",[x,e]);var g=x.onreadystatechange=function(q){if(!x||x.readyState===0||q==="abort"){E||

d();E=true;if(x)x.onreadystatechange=c.noop}else if(!E&&x&&(x.readyState===4||q==="timeout")){E=true;x.onreadystatechange=c.noop;i=q==="timeout"?"timeout":!c.httpSuccess(x)?"error":e.ifModified&&c.httpNotModified(x,e.url)?"notmodified":"success";var p;if(i==="success")try{o=c.httpData(x,e.dataType,e)}catch(v){i="parsererror";p=v}if(i==="success"||i==="notmodified")j||b();else c.handleError(e,x,i,p);d();q==="timeout"&&x.abort();if(e.async)x=null}};try{var h=x.abort;x.abort=function(){x&&h.call(x);

g("abort")}}catch(l){}e.async&&e.timeout>0&&setTimeout(function(){x&&!E&&g("timeout")},e.timeout);try{x.send(n==="POST"||n==="PUT"||n==="DELETE"?e.data:null)}catch(m){c.handleError(e,x,null,m);d()}e.async||g();return x}},handleError:function(a,b,d,f){if(a.error)a.error.call(a.context||a,b,d,f);if(a.global)(a.context?c(a.context):c.event).trigger("ajaxError",[b,a,f])},active:0,httpSuccess:function(a){try{return!a.status&&location.protocol==="file:"||a.status>=200&&a.status<300||a.status===304||a.status=== 1223||a.status===0}catch(b){}return false},httpNotModified:function(a,b){var d=a.getResponseHeader("Last-Modified"),f=a.getResponseHeader("Etag");if(d)c.lastModified[b]=d;if(f)c.etag[b]=f;return a.status===304||a.status===0},httpData:function(a,b,d){var f=a.getResponseHeader("content-type")||"",e=b==="xml"||!b&&f.indexOf("xml")>=0;a=e?a.responseXML:a.responseText;e&&a.documentElement.nodeName==="parsererror"&&c.error("parsererror");if(d&&d.dataFilter)a=d.dataFilter(a,b);if(typeof a==="string")if(b===

"json"||!b&&f.indexOf("json")>=0)a=c.parseJSON(a);else if(b==="script"||!b&&f.indexOf("javascript")>=0)c.globalEval(a);return a},param:function(a,b){function d(i,o){if(c.isArray(o))c.each(o,function(k,n){b||/\[\]$/.test(i)?f(i,n):d(i+"["+(typeof n==="object"||c.isArray(n)?k:"")+"]",n)});else!b&&o!=null&&typeof o==="object"?c.each(o,function(k,n){d(i+"["+k+"]",n)}):f(i,o)}function f(i,o){o=c.isFunction(o)?o():o;e[e.length]=encodeURIComponent(i)+"="+encodeURIComponent(o)}var e=[];if(b===w)b=c.ajaxSettings.traditional;

if(c.isArray(a)||a.jquery)c.each(a,function(){f(this.name,this.value)});else for(var j in a)d(j,a[j]);return e.join("&").replace(yb,"+")}});var la={},Ab=/toggle|show|hide/,Bb=/^([+-]=)?([\d+-.]+)(.*)$/,W,va=[["height","marginTop","marginBottom","paddingTop","paddingBottom"],["width","marginLeft","marginRight","paddingLeft","paddingRight"],["opacity"]];c.fn.extend({show:function(a,b){if(a||a===0)return this.animate(K("show",3),a,b);else{a=0;for(b=this.length;a").appendTo("body");f=e.css("display");if(f==="none")f="block";e.remove();la[d]=f}c.data(this[a],"olddisplay",f)}}a=0;for(b=this.length;a=0;f--)if(d[f].elem===this){b&&d[f](true);d.splice(f,1)}});b||this.dequeue();return this}});c.each({slideDown:K("show",1),slideUp:K("hide",1),slideToggle:K("toggle",1),fadeIn:{opacity:"show"},fadeOut:{opacity:"hide"}},function(a,b){c.fn[a]=function(d,f){return this.animate(b,d,f)}});c.extend({speed:function(a,b,d){var f=a&&typeof a==="object"?a:{complete:d||!d&&b||c.isFunction(a)&&a,duration:a,easing:d&&b||b&&!c.isFunction(b)&&b};f.duration=c.fx.off?0:typeof f.duration===

"number"?f.duration:c.fx.speeds[f.duration]||c.fx.speeds._default;f.old=f.complete;f.complete=function(){f.queue!==false&&c(this).dequeue();c.isFunction(f.old)&&f.old.call(this)};return f},easing:{linear:function(a,b,d,f){return d+f*a},swing:function(a,b,d,f){return(-Math.cos(a*Math.PI)/2+0.5)*f+d}},timers:[],fx:function(a,b,d){this.options=b;this.elem=a;this.prop=d;if(!b.orig)b.orig={}}});c.fx.prototype={update:function(){this.options.step&&this.options.step.call(this.elem,this.now,this);(c.fx.step[this.prop]||

c.fx.step._default)(this);if((this.prop==="height"||this.prop==="width")&&this.elem.style)this.elem.style.display="block"},cur:function(a){if(this.elem[this.prop]!=null&&(!this.elem.style||this.elem.style[this.prop]==null))return this.elem[this.prop];return(a=parseFloat(c.css(this.elem,this.prop,a)))&&a>-10000?a:parseFloat(c.curCSS(this.elem,this.prop))||0},custom:function(a,b,d){function f(j){return e.step(j)}this.startTime=J();this.start=a;this.end=b;this.unit=d||this.unit||"px";this.now=this.start;

this.pos=this.state=0;var e=this;f.elem=this.elem;if(f()&&c.timers.push(f)&&!W)W=setInterval(c.fx.tick,13)},show:function(){this.options.orig[this.prop]=c.style(this.elem,this.prop);this.options.show=true;this.custom(this.prop==="width"||this.prop==="height"?1:0,this.cur());c(this.elem).show()},hide:function(){this.options.orig[this.prop]=c.style(this.elem,this.prop);this.options.hide=true;this.custom(this.cur(),0)},step:function(a){var b=J(),d=true;if(a||b>=this.options.duration+this.startTime){this.now=

this.end;this.pos=this.state=1;this.update();this.options.curAnim[this.prop]=true;for(var f in this.options.curAnim)if(this.options.curAnim[f]!==true)d=false;if(d){if(this.options.display!=null){this.elem.style.overflow=this.options.overflow;a=c.data(this.elem,"olddisplay");this.elem.style.display=a?a:this.options.display;if(c.css(this.elem,"display")==="none")this.elem.style.display="block"}this.options.hide&&c(this.elem).hide();if(this.options.hide||this.options.show)for(var e in this.options.curAnim)c.style(this.elem,

e,this.options.orig[e]);this.options.complete.call(this.elem)}return false}else{e=b-this.startTime;this.state=e/this.options.duration;a=this.options.easing||(c.easing.swing?"swing":"linear");this.pos=c.easing[this.options.specialEasing&&this.options.specialEasing[this.prop]||a](this.state,e,0,1,this.options.duration);this.now=this.start+(this.end-this.start)*this.pos;this.update()}return true}};c.extend(c.fx,{tick:function(){for(var a=c.timers,b=0;b

";

a.insertBefore(b,a.firstChild);d=b.firstChild;f=d.firstChild;e=d.nextSibling.firstChild.firstChild;this.doesNotAddBorder=f.offsetTop!==5;this.doesAddBorderForTableAndCells=e.offsetTop===5;f.style.position="fixed";f.style.top="20px";this.supportsFixedPosition=f.offsetTop===20||f.offsetTop===15;f.style.position=f.style.top="";d.style.overflow="hidden";d.style.position="relative";this.subtractsBorderForOverflowNotVisible=f.offsetTop===-5;this.doesNotIncludeMarginInBodyOffset=a.offsetTop!==j;a.removeChild(b);

c.offset.initialize=c.noop},bodyOffset:function(a){var b=a.offsetTop,d=a.offsetLeft;c.offset.initialize();if(c.offset.doesNotIncludeMarginInBodyOffset){b+=parseFloat(c.curCSS(a,"marginTop",true))||0;d+=parseFloat(c.curCSS(a,"marginLeft",true))||0}return{top:b,left:d}},setOffset:function(a,b,d){if(/static/.test(c.curCSS(a,"position")))a.style.position="relative";var f=c(a),e=f.offset(),j=parseInt(c.curCSS(a,"top",true),10)||0,i=parseInt(c.curCSS(a,"left",true),10)||0;if(c.isFunction(b))b=b.call(a,

d,e);d={top:b.top-e.top+j,left:b.left-e.left+i};"using"in b?b.using.call(a,d):f.css(d)}};c.fn.extend({position:function(){if(!this[0])return null;var a=this[0],b=this.offsetParent(),d=this.offset(),f=/^body|html$/i.test(b[0].nodeName)?{top:0,left:0}:b.offset();d.top-=parseFloat(c.curCSS(a,"marginTop",true))||0;d.left-=parseFloat(c.curCSS(a,"marginLeft",true))||0;f.top+=parseFloat(c.curCSS(b[0],"borderTopWidth",true))||0;f.left+=parseFloat(c.curCSS(b[0],"borderLeftWidth",true))||0;return{top:d.top-

f.top,left:d.left-f.left}},offsetParent:function(){return this.map(function(){for(var a=this.offsetParent||s.body;a&&!/^body|html$/i.test(a.nodeName)&&c.css(a,"position")==="static";)a=a.offsetParent;return a})}});c.each(["Left","Top"],function(a,b){var d="scroll"+b;c.fn[d]=function(f){var e=this[0],j;if(!e)return null;if(f!==w)return this.each(function(){if(j=wa(this))j.scrollTo(!a?f:c(j).scrollLeft(),a?f:c(j).scrollTop());else this[d]=f});else return(j=wa(e))?"pageXOffset"in j?j[a?"pageYOffset":

"pageXOffset"]:c.support.boxModel&&j.document.documentElement[d]||j.document.body[d]:e[d]}});c.each(["Height","Width"],function(a,b){var d=b.toLowerCase();c.fn["inner"+b]=function(){return this[0]?c.css(this[0],d,false,"padding"):null};c.fn["outer"+b]=function(f){return this[0]?c.css(this[0],d,false,f?"margin":"border"):null};c.fn[d]=function(f){var e=this[0];if(!e)return f==null?null:this;if(c.isFunction(f))return this.each(function(j){var i=c(this);i[d](f.call(this,j,i[d]()))});return"scrollTo"in

e&&e.document?e.document.compatMode==="CSS1Compat"&&e.document.documentElement["client"+b]||e.document.body["client"+b]:e.nodeType===9?Math.max(e.documentElement["client"+b],e.body["scroll"+b],e.documentElement["scroll"+b],e.body["offset"+b],e.documentElement["offset"+b]):f===w?c.css(e,d):this.css(d,typeof f==="string"?f:f+"px")}});A.jQuery=A.$=c})(window);

Contact us

Telephone:(852) 2838 3620

Email:sales@silverwing.com.hk

Address: Unit 2, 4/F, Kwai Cheong Centre, 50 Kwai Cheong Road, Kwai Chung, New Territories, Hong Kong

Discussion on the Application of Nanotechnology in Lithium Ion Batteries

Source:

Time:2017-06-23 10:36:51

views:

Lithium-ion battery as a highly efficient energy storage components, has been widely used in the field of consumer electronics, mobile phones to laptops have lithium-ion battery figure, lithium-ion battery made such a brilliant result thanks to its high energy density, As well as good safety performance. With the continuous development of technology, lithium-ion battery energy density, power density is also constantly improve, which made nanotechnology made an indelible contribution.

Speaking of nano-technology in the application of lithium-ion battery, Xiao Bian first thought is LiFePO4, LiFePO4 due to poor conductivity, in order to improve its conductivity, people prepared into nano-particles, greatly improved LiFePO4 Chemical properties. In addition, silicon anode is also the beneficiaries of nanotechnology, nano-silicon particles is a good inhibition of Si in the process of lithium in the volume expansion, improve the Si material cycle performance.

Jun Lu, a national laboratory in Argonne, recently published an article in the journal Naturenaotechnology, summarizing and reviewing the application of nanotechnology in lithium-ion batteries.

Cathode material

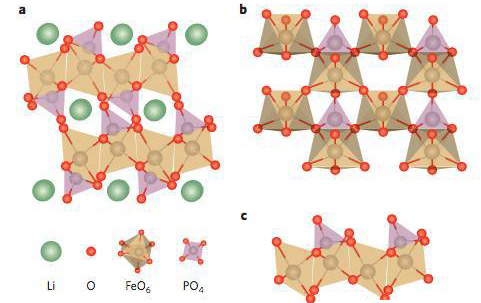

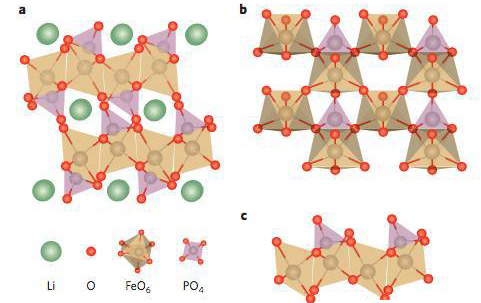

1、LiFePO4 material

LiFePO4 material has good thermal stability and low cost, attracting people's attention, but because of the unique covalent bond structure of LiFePO4 material, the electron conductivity of LFP material is very low, thus limiting its high rate charge and discharge performance, For this purpose, LFP materials are made into nanoparticles and coated with materials such as conductive materials such as carbon, conductive polymers, and metals. In addition, it has been found that the electron conductivity of LFP nanoparticles can be increased by 108 by adding non-stoichiometric solid solution doping method into nano-LFP particles, so that LFP material can be charged and discharged within 3min, This is especially important for electric vehicles.

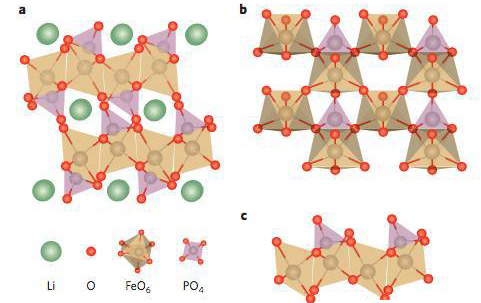

Figure a shows the crystal mechanism of the LFP crystal in the (010) direction. The "PO6" octahedron in the crystal is connected together by means of a common O atom. This connection also leads to a low electrical conductivity of the material. In addition, another problem that affects the performance of LFP material is the Fe occupying problem. In the 1D direction, Li + has a high diffusion coefficient, but some Fe occupies the position of Li, which affects the diffusion rate of Li in the (001) direction , Resulting in material polarization, magnification performance is poor.

2、 inhibition of LiMn2O4 material decomposition

LMO material has a three-dimensional Li + diffusion channel, so it has a high ion diffusion coefficient, but in the low SoC state will form Mn3 +, due to the existence of Jonh-Teller effect, resulting in LMO structure instability, part of the Mn element dissolved into the electrolyte, And finally deposited onto the surface of the negative electrode, destroying the structure of the SEI film. At present, a solution is to add some low-cost main group metal ions, such as Li, to replace part of Mn in LMO, thereby increasing the valence of Mn elements at low SoC and reducing Mn3 +. Another solution is to coat the surface of the LMO material particles with a layer of 10-20nm thickness of oxides, fluorides, such as ZrO2, TiO2 and SiO2.

3、inhibit the chemical activity of NMC

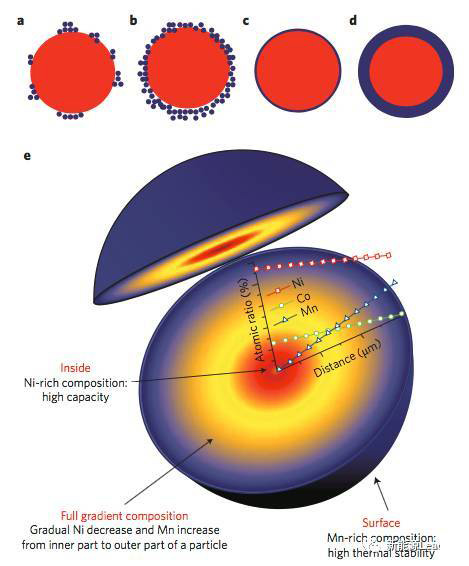

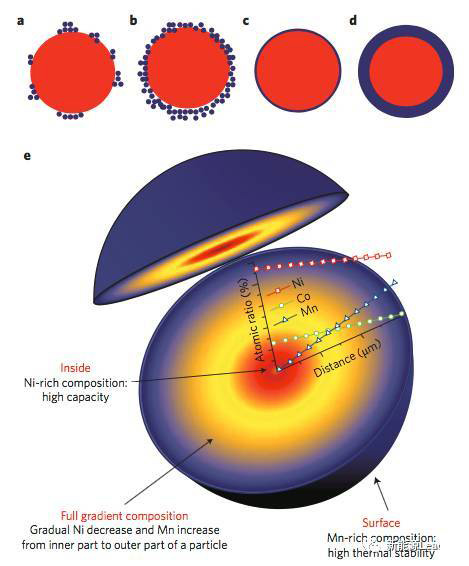

NMC materials, especially high nickel NMC material specific capacity up to 200mAh / g or more, and has a very excellent cycle performance. However, in the state of charge, the NMC material is very easy to cause oxidation of the electrolyte, so in actual production, we do not want to make the NMC material into nanoparticles, but we can inhibit the chemical activity of NMC by nano-coating.

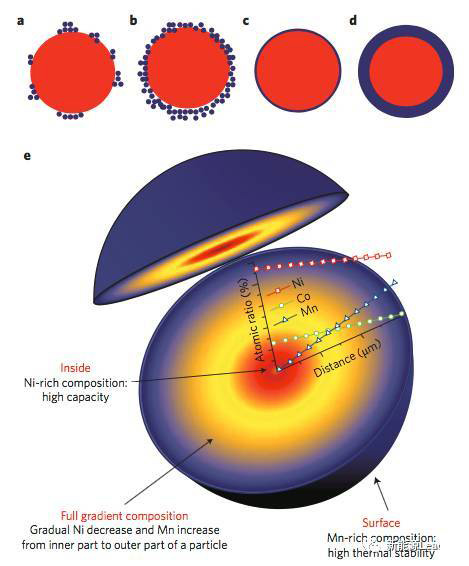

In order to suppress the reactivity of high nickel NMC materials with electrolytes, people try to use nano-particles on the coating process to avoid direct contact of material particles and electrolyte, which greatly improve the material's cycle life, as shown in Figure a, b As shown. Atomic layer deposition is also an important method to protect NMC materials, studies have shown that 3 to 5 times the atomic layer deposition can get the best performance of the NMC material. However, due to the lack of acidic functional groups on the surface of NMC materials, it is difficult to effectively carry out atomic layer deposition. In addition, the core-shell structure of the nanoparticles is also an effective way to reduce the reactivity, as shown in Figure 3d, high Mn shell has good stability, but the capacity is low, high nickel core capacity is high, but the reactivity, but this structure Another problem is that the internal stress caused by the lattice mismatch affects the cycle performance of the material. This problem can be solved by the gradient concentration material. As shown in Fig. 3e, the concentration of Ni gradually decreases from the core to the shell. Material can reach more than 200mAh / g high reversible capacity, and has up to 1000 times the cycle life.

2、 inhibition of LiMn2O4 material decomposition

LMO material has a three-dimensional Li + diffusion channel, so it has a high ion diffusion coefficient, but in the low SoC state will form Mn3 +, due to the existence of Jonh-Teller effect, resulting in LMO structure instability, part of the Mn element dissolved into the electrolyte, And finally deposited onto the surface of the negative electrode, destroying the structure of the SEI film. At present, a solution is to add some low-cost main group metal ions, such as Li, to replace part of Mn in LMO, thereby increasing the valence of Mn elements at low SoC and reducing Mn3 +. Another solution is to coat the surface of the LMO material particles with a layer of 10-20nm thickness of oxides, fluorides, such as ZrO2, TiO2 and SiO2.

3、inhibit the chemical activity of NMC

NMC materials, especially high nickel NMC material specific capacity up to 200mAh / g or more, and has a very excellent cycle performance. However, in the state of charge, the NMC material is very easy to cause oxidation of the electrolyte, so in actual production, we do not want to make the NMC material into nanoparticles, but we can inhibit the chemical activity of NMC by nano-coating.

In order to suppress the reactivity of high nickel NMC materials with electrolytes, people try to use nano-particles on the coating process to avoid direct contact of material particles and electrolyte, which greatly improve the material's cycle life, as shown in Figure a, b As shown. Atomic layer deposition is also an important method to protect NMC materials, studies have shown that 3 to 5 times the atomic layer deposition can get the best performance of the NMC material. However, due to the lack of acidic functional groups on the surface of NMC materials, it is difficult to effectively carry out atomic layer deposition. In addition, the core-shell structure of the nanoparticles is also an effective way to reduce the reactivity, as shown in Figure 3d, high Mn shell has good stability, but the capacity is low, high nickel core capacity is high, but the reactivity, but this structure Another problem is that the internal stress caused by the lattice mismatch affects the cycle performance of the material. This problem can be solved by the gradient concentration material. As shown in Fig. 3e, the concentration of Ni gradually decreases from the core to the shell. Material can reach more than 200mAh / g high reversible capacity, and has up to 1000 times the cycle life.

Negative material

1、graphite material protection

Graphite material with low lithium intercalation voltage (0.15-0.25V vs Li + / Li) is very suitable as a negative electrode for lithium ion batteries, but graphite materials have some drawbacks. Lithium after the graphite has a strong reactivity, will react with the organic electrolyte, resulting in graphite sheet off and electrolyte decomposition, SEI film can inhibit the decomposition of the electrolyte, but the SEI film can not be 100% of the graphite negative Form protection. At present, common graphite surface protection Pocons methods are surface oxidation and nano-coating technology.

Nano-coating technology includes: amorphous carbon, metal and metal oxide three categories, of which amorphous carbon is mainly through the vacuum chemical deposition CVD method, this method is low cost, suitable for large-scale production. Metal and metal oxide nano-coating is mainly obtained by wet chemical method (plating), can be a good protection of graphite to prevent electrolyte decomposition.

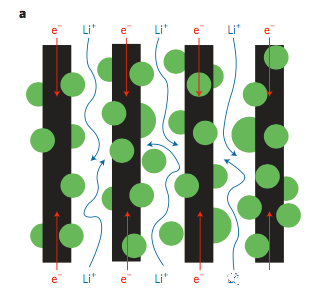

2、to enhance the lithium titanate LTO and TiO2 material magnification performance

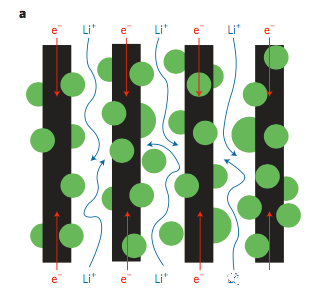

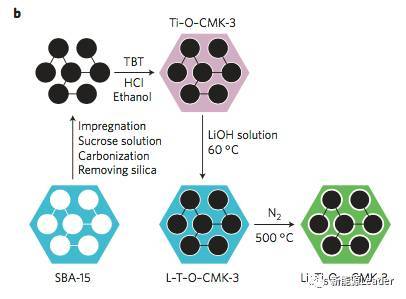

LTO (Li4Ti5O12) material is highly safe, and does not generate stress during Li embedding and deintercalation. The lithium intercalation potential is high and does not cause the decomposition of the electrolyte. It is a very excellent anode material, but the LTO material is also facing Problem: 1) low specific capacity, theoretical specific capacity of only 175mAh / g; 2) low electron and ionic conductivity. At present, nanotechnology in the LTO mainly in the following three aspects of the application: 1) nano-particles; 2) nano-coating technology; 3) LTO nano-materials and conductive materials composite. LTO nanocrystallization can effectively reduce the diffusion distance of Li + and increase the contact area of LTO in the electrolyte. Nano-coating technology can enhance the charge exchange between LTO and electrolyte to improve the rate performance. Several common nano-coating techniques are shown in the following figure, where a shows the composite structure of nanometer TiO2 and porous carbon. Figure b shows how to prepare LTO + CMK-3 mesoporous carbon composites.

Negative material

1、graphite material protection

Graphite material with low lithium intercalation voltage (0.15-0.25V vs Li + / Li) is very suitable as a negative electrode for lithium ion batteries, but graphite materials have some drawbacks. Lithium after the graphite has a strong reactivity, will react with the organic electrolyte, resulting in graphite sheet off and electrolyte decomposition, SEI film can inhibit the decomposition of the electrolyte, but the SEI film can not be 100% of the graphite negative Form protection. At present, common graphite surface protection Pocons methods are surface oxidation and nano-coating technology.

Nano-coating technology includes: amorphous carbon, metal and metal oxide three categories, of which amorphous carbon is mainly through the vacuum chemical deposition CVD method, this method is low cost, suitable for large-scale production. Metal and metal oxide nano-coating is mainly obtained by wet chemical method (plating), can be a good protection of graphite to prevent electrolyte decomposition.

2、to enhance the lithium titanate LTO and TiO2 material magnification performance

LTO (Li4Ti5O12) material is highly safe, and does not generate stress during Li embedding and deintercalation. The lithium intercalation potential is high and does not cause the decomposition of the electrolyte. It is a very excellent anode material, but the LTO material is also facing Problem: 1) low specific capacity, theoretical specific capacity of only 175mAh / g; 2) low electron and ionic conductivity. At present, nanotechnology in the LTO mainly in the following three aspects of the application: 1) nano-particles; 2) nano-coating technology; 3) LTO nano-materials and conductive materials composite. LTO nanocrystallization can effectively reduce the diffusion distance of Li + and increase the contact area of LTO in the electrolyte. Nano-coating technology can enhance the charge exchange between LTO and electrolyte to improve the rate performance. Several common nano-coating techniques are shown in the following figure, where a shows the composite structure of nanometer TiO2 and porous carbon. Figure b shows how to prepare LTO + CMK-3 mesoporous carbon composites.

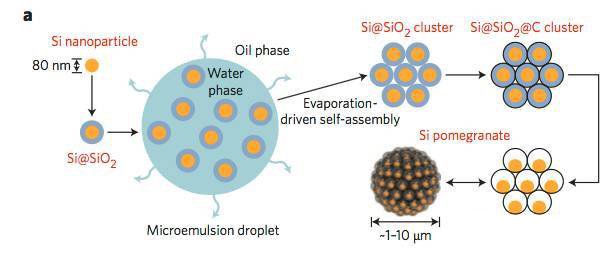

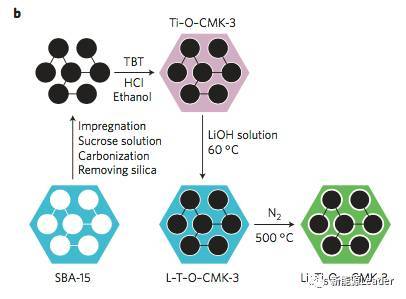

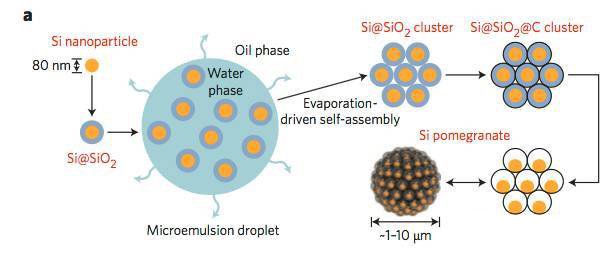

3、 to improve the energy density of silicon negative

Si material theoretical specific capacity of 3572mAh / g, much higher than the graphite material, thus attracting a wide range of attention, but Si in the process of intercalation and de-lithium will produce up to 300% of the volume expansion, resulting in particle fragmentation and active substances In order to overcome this shortcoming, people will be made of nano-particles of nano-particles in order to ease the expansion of Si particles produced by the mechanical stress. At present, other Si nanostructures include 1-dimensional nanowires, 1-dimensional nanowires can form good contact with the current collector and electrolyte, and leave enough space for Si expansion, so the reversible specific capacity of the material up to 2000mAh / G, and has good cycle performance.

Application of nanotechnology in Li-S batteries

Li-S battery has a high energy density and low cost, and is a promising next generation of energy storage battery. However, Li-S battery currently faces the main problem that S has low conductivity and dissolves lithium products. In order to solve this problem Problem A variety of composite nanomaterials are used, for example, by combining S with porous hollow carbon or metal oxide nanoparticles, which can significantly improve the stability of S and improve the cycling performance of the electrode. In addition, S and graphene material composite can also significantly improve the S negative performance of the cycle.

Application of nanotechnology in Li-S batteries

Li-S battery has a high energy density and low cost, and is a promising next generation of energy storage battery. However, Li-S battery currently faces the main problem that S has low conductivity and dissolves lithium products. In order to solve this problem Problem A variety of composite nanomaterials are used, for example, by combining S with porous hollow carbon or metal oxide nanoparticles, which can significantly improve the stability of S and improve the cycling performance of the electrode. In addition, S and graphene material composite can also significantly improve the S negative performance of the cycle.