In the long term, Industry 4.0 will invest far more in smart factories than the average industry, but its profitability will also increase significantly. And the larger the capital investment, the steeper the slope is, and the higher the marginal return on investment is. No matter what kind of economy, Industry 4.0 will be the only way for the development of manufacturing industry. We have always focused on the field of industrial control, but also deeply felt the industrialization of the intelligent manufacturing to bring the changes brought about by the Internet of Things has been continuously into the industrial manufacturing, in our cooperation in the enterprise, real-time industrial production data Acquisition (such as MES system) is considered typical, and in the industrial production information network, zigbee deserved to become the protagonist.

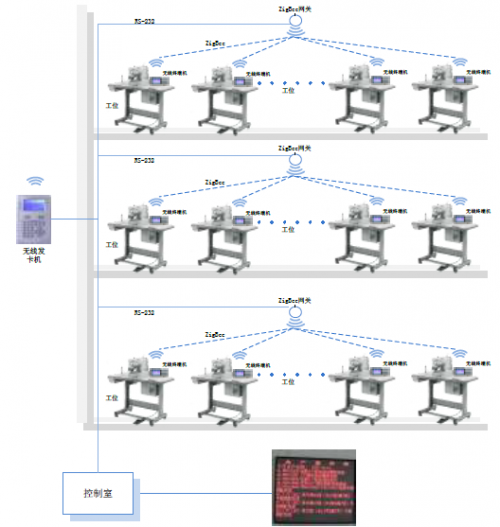

Figure 1 using zigbee to build the production of information management network

The MES system is a set of production information management system that is the most basic for the execution layer of the manufacturing enterprise workshop. It can provide information management including manufacturing data management, schedule management, production scheduling management, inventory management, quality management, tooling management, purchasing management , The underlying data integration analysis, decomposition of the upper data integration management module. It is the bond of enterprise CIMS information integration, and is the basic technical means to implement the agile manufacturing strategy and to realize the agile production in the workshop. MES is the rapid development of the world in the past 10 years, facing the shop floor production management technology and real-time information system. MES can provide users with a fast response, flexible and meticulous manufacturing environment, helping enterprises to reduce costs, delivery on schedule, improve product quality and improve service quality. It is suitable for different industries (home appliances, automobiles, semiconductors, telecommunications, IT, pharmaceuticals) to provide a good enterprise information management for a single high-volume production and hybrid manufacturing enterprises that have both small-batch production and mass production.

Figure 2 applies to the system zigbee wireless module AW824P2

Throughout the system, zigbee module through robust networking transparent transmission protocol, can build a variety of types of network topology, the entire manufacturing system for information networking, and access through the gateway to the Ethernet to achieve Intelligent management, and mature applications in a variety of complex plant environment.

Figure 3 user MES hardware system exhibition

At present, 44% of the major industrial sectors in Germany have adopted the "Industry 4.0" related production and technology models. There are more and more domestic manufacturing enterprises and factories moving forward in this direction, which fully shows that Industry 4.0 has changed from a concept to a reality.

Figure 4 Smart Factory Model

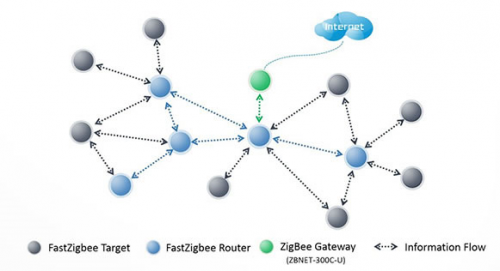

However, we know that at present, many zigbee are similar to zigbeePro, Home Automation, and Smart Enengy. However, during the networking process, node dropouts tend to occur, and the communication efficiency is low and the number of supported nodes is small. In view of these situations, Focused on the application of these parameters have higher requirements, developed a set of industrial applications fast networking communication protocol - Fastzigbee, the protocol's main features is to support more nodes, overcoming zigbee node dropped, easy to use, Flexible and efficient, suitable for all types of networking functions. At the same time to achieve zero threshold zigbee networking.

Traditional zigbee protocol: zigbee agreement to understand, based on third-party library programming development, test network robustness and stability and repeated debugging, planning application network, start waiting for networking, zigbee communication;

Fastzigbee protocol: black box, software configuration, network cloth, zigbee network communication.

Figure 5 zigbee protocol comparison

Traditional zigbee protocol node types are divided into three types: coordinator, router, terminal node. Users develop their own need from the bottom of the zigbee communication mechanism to the user a comprehensive understanding of the API master, and because of the complexity of the wireless protocol and wireless experimental platform environment to build the high cost, resulting in more than 50% of users have hidden problems zigbee communication .

Figure 6 zigbee topology

zigbee Currently the most used network communications, such as peer-to-peer communications, master-slave mode (point to multipoint) communications, networking communications. These three kinds of communication are the most common and relatively simple networks currently used by zigbee. Traditional zigbee communication protocol, response to these networks need to be assigned roles, set the relative trouble, slow networking time, communication efficiency is not high, and the application is not flexible. Fastzigbee can easily deal with these networks, giving customers the ultimate user experience, while Fastzigbee also meet zigbee's network specification.

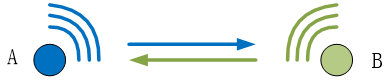

1, as shown in FIG. 7, simply point the destination node addresses of A and B points to each other, and then realize the data transmission between A and B points. Settings can be used with supporting Fastzigbee configuration software, open the serial port - access to information - modify the configuration, you can easily complete the configuration.

Figure 7 point to point communication diagram

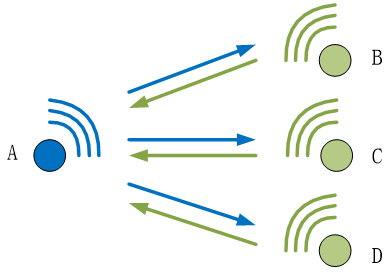

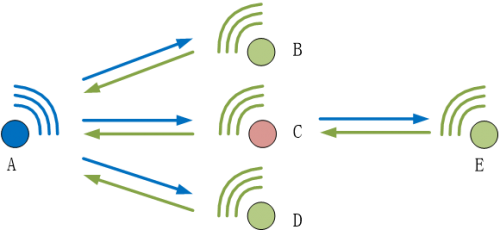

2. As shown in Figure 8, master-slave mode (point-to-multipoint) communication only needs to point the destination node addresses of slave nodes such as B, C, D to master node A, set A to broadcast, or switch Target address (without restart) instruction, you can achieve AB, C, D nodes such as multi-point transparent data transmission. Similarly set up only use the matching Fastzigbee configuration software can be.

Figure 8 master-slave mode (point to multipoint) communication diagram

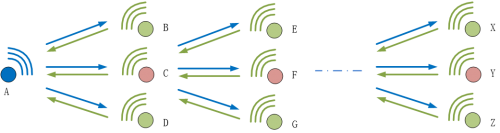

3, as shown in Figure 9, when the distance between the master and slave nodes can not directly communicate, Harvatek only needs to set a node in the distance between two points (eg point C) as the routing mode to complete data forwarding. All other settings are the same as those in 2 o'clock the same settings.

Figure 9 Networking diagram of forwarding

4, from the above three basic network, to expand a more complex network, as shown in Figure 10 below, multi-level networking communications. Fastzigbee agreement to deal with the network is also handy, completely the same way and the first three settings, just the link can not reach the middle distance, find a node, set to routing mode. Fastzigbee maximum support 10 routing forwarding, maximum single-level routing 2.5KM, to meet most of the network.

Figure 10 multi-level networking diagram

Fastzigbee has been used in a large number of MES system hardware to provide a stable and reliable networking communication solution for intelligent manufacturing. We will also continuously provide new blood to the smart factory, from manufacturing to manufacturing in China, which is the grand time of Industry 4.0 Combining Big Data, Cloud Computing Technology and Mobile Internet, Chinese companies can keep abreast of the market and establish a new type of interaction with users and gain insight into users' needs. A new generation of IT technology can also help the whole industry integration and cross-industry, service sector integration, play the Chinese industry's "team advantage." We will also launch more industrial 4.0 components, support the formation and implementation of "Industry 4.0" with Chinese characteristics, help all walks of life in China to innovate and upgrade, and further promote China's economic restructuring.