ABCO can develop the best quality and high performance components based on customer needs and the environment.

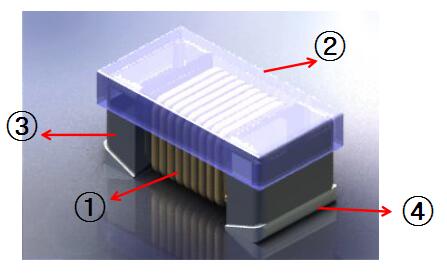

1、The structure of ABCO wire wound SMD chip inductor

① WIND WIRE : WIRE FOR INDUCTANCE

② UV GLUE : MOLDING FOR PICKUP AS SMT

③ BODY : DIVIDE BETWEEN FERRITE AND CERAMIC BOBBIN

ACCORDING TO BUYER’S NEED

④ TERMINAL :Ag – Paste +Ni + Sn

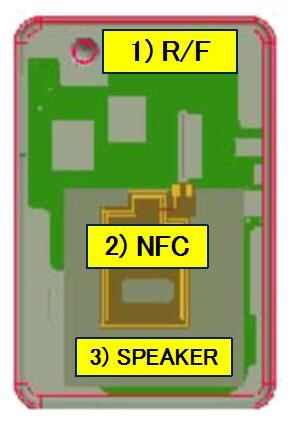

2、The use of ABCO wire wound SMD chip inductors

1) FREQUENCY MATCHING

Strongly recommend high frequency ceramic chip wirewound inductors for high Q, J (± 5%) tolerances.

ABCO Parts Recommendation: ABCO NO. LMC1005, LMC1608, LMC2012

New version of the second half of 2015: ABCO NO. LMC0604, LMC0603

2) IMPROVEMENT OF TAG DISTANCE

Strongly recommend high inductance ferrite core wire wound inductors to achieve (± 5%) tolerances.

ABCO Parts Recommendation: LMF1005-N, LMF1608-N

Meets LMF1005-N and LMF0805 highly recommended harmonic distortion factors for low core losses, low RDC and excellent J (± 5%) tolerances.

ABCO Parts Recommendation: LMF1005-N, LMF0805

New version in the second half of 2015: ULTRA SMALL SIZE OF LMF0604, LMF0603 SERIES

ABCO 2015 NEW ITEM:

LMF0604:To achieve the world's first ultrasonic wirewound inductors and ultra-thin size.

|

ITEM |

Current LMF1005 |

New product LMF0604 |

Effect |

|

LENGTH |

1.02mm |

0.60mm |

53% DECREASING SIZE |

|

WIDTH |

0.56mm |

0.45mm |

|

|

SMT SIZE |

0.57m^2 |

0.27m^2 |

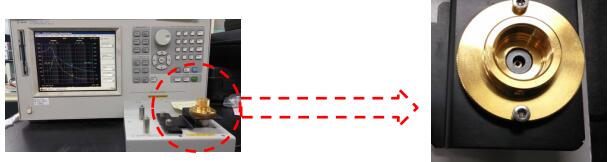

ABCO Evaluation Technique:

As ABCO developed to Ferrite Core. We can select core’s permeability according to customer’s needs and evaluate them under customer’s optimization.

- SGX MiCS-4514 is a compact MOS sensor

- POCONS RF CABLE CLIP SMD TYPE PCC1009

- Transistor TO92 faces discontinued or out of stock, Central can be replaced

- Corporate merger of Carling & Littelfuse

- SILVER WING Group wishes you have a happy holidays

- Sangshin new product --- GPS Module

- Silver Wing 2018 annual summary and 20th anniversary celebration